Table of Contents Biologists think the human nose can distinguish about 10,000 odors. A dog’s nose can distinguish about 2 million different odors, and it

Fixed Gas Detector

The fixed gas detector is used to monitor the gas concentration in your warehouse and workplace. When the concentration exceeds the preset alarm value, it will send out an audible and visual alarm signal to remind users to take safety measures in time. This explosion-proof gas detector has a variety of gases to choose from, such as O2, H2, H2S, CO, CH4, SO2, NO2, NH3, PH3, O3, SF6, etc.

- Model: RS-FPC-*-*

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: $85.5~$249.5

About - Fixed gas detector

This explosion-proof gas detector can choose many types of gases, including carbon dioxide, hydrogen, carbon monoxide, hydrogen sulfide, methane, nitrogen dioxide, sulfur dioxide, formaldehyde, oxygen, ammonia, ozone, etc. There are also a variety of gas measurement ranges and support customization.

Fixed gas detector description

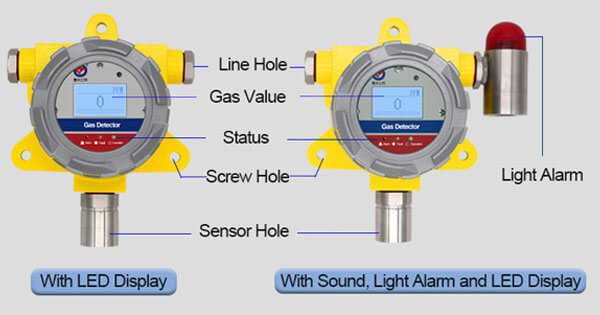

The RS-FPC-*-* fixed gas leak detector has a built-in electrochemical sensor of a big brand, which is sensitive in the use process and has a strong anti-interference ability. After our unique compensation algorithm and multi-stage standard gas calibration, it has the characteristics of long life, high precision, and good stability. The appearance of the industrial gas detector adopts a large-screen LCD, the protection level is IP65, and the explosion-proof mark: Ex d IIC T6 Gb, which can be applied to the harsh outdoor environment.

Fixed gas detector features

1. Using remote infrared remote control technology, parameters can be modified without disassembly.

2. Support a variety of gas detection, and the range can be customized.

3. There are multiple output modes such as analog quantity and RS485 for selection.

4. Optional high-quality LCD, the value can be viewed directly on-site.

5. 10~30V DC wide-voltage power supply, which can adapt to a variety of on-site DC power supplies.

6. The gas detector adopts a wall-mounted waterproof case, which is easy to install.

Video - Fixed gas detector

Product type: RS-FPCA- gas detector

Detecting gas: H2/CO/H2S/CH4/NO2/SO2/CH2O/O2/NH3/O3

Explosion-proof grade: Exd ⅡC T6 Gb

Response time: <30S

Power supply: DC24V±10%

Working temperature: -20℃~50℃

Working humidity: 0-95%RH (no dew)

Output signal: RS485

Installation method: Wall-mounted

Shell material: Aluminum

Dimensions: 190*150*95mm(L*W*H)

Weight: ≤ 1.6kg

| Detected gas | Detecting scope | Resolution | Low/High Alarm Point | Response time | Accuracy |

|---|---|---|---|---|---|

| O2 | 0-30%VOL | 0.1%VOL | 19.5%VOL/23%VOL | ≤10s | ±2%FS |

| H2S | 0-100PPM | 1PPM | 10PPM/20PPM | ≤35s | ±2ppm or ±10% |

| CH4 | 0-100%LEL | 1%LEL | 25%LEL/50%LEL | ≤15s | ±5%FS |

| CO | 0-1000PPM | 1PPM | 50PPM/100PPM | ≤30s | ±5ppm or ±10% |

| NO2 | 0-20PPM | 0.1PPM | 3PPM/10PPM | ≤15s | ±5%FS |

| SO2 | 0-20PPM | 0.1PPM | 5PPM/10PPM | ≤45s | ±5ppm or ±10% |

| H2 | 0-1000PPM | 1PPM | 50PPM/100PPM | ≤70s | ±5%FS |

| NH3 | 0-100PPM | 1PPM | 25PPM/50PPM | ≤90s | ±8% |

FAQS

What is fixed gas detection?

Fixed gas detection is suitable for uncontrolled or public areas where access is not restricted or difficult to control, and there may be gas hazards. Fixed gas detection can be temporary, requiring 24/7 monitoring for a short period.

What are the types of gas detectors?

According to the principle of gas sensors, it can be divided into the infrared gas detector, thermomagnetic gas detector, electrochemical gas detector, semiconductor gas detector, ultraviolet gas detector, and so on.

What does F.S stand for?

F. S is the acronym for full scale. It indicates the size of the measurement range. We often encounter customers asking us what is the accuracy of the detector? Our accurate answer is less than or equal to ±2% F.S, where F.S means full scale

How to maintain the fixed gas detector?

Wipe clean the surface regularly with a soft damp cloth.

Where to use a fixed gas detector?

Fixed gas detectors can measure a wide range of gases, and can be used in petrochemical, coal, metallurgy, chemical, municipal gas, environmental monitoring, and other places to detect on-site. It can meet the measurement needs of special occasions. Gas concentration detection or leak detection can be performed on tunnels, pipelines, tanks, confined spaces, etc.

What is fixed gas detection system?

The purpose of installing a fixed gas detection system is to provide 24/7 continuous, area and personnel protection. These detection systems are designed to warn workers of the potential danger of poisoning due to exposure to toxic gases, suffocation due to lack of oxygen, or explosions due to combustible gases.

Where should a fixed gas detector be mounted?

- To detect gases lighter than air (such as methane and ammonia), a fixed gas detector should be installed at a higher position, and a conical collector should be used.

- To detect gases heavier than air (such as butane and sulfur dioxide), the detector should be installed at a lower position.

- Consider the possible behavior of escaping gas under the action of natural and pressurized airflow. Install the detector in the ventilation duct when appropriate.

- When determining the location of the detector, it is necessary to consider the damage that may be caused by natural events (such as rain or flood). For detectors installed outdoors, use weatherproof devices.

- If it is installed in a hot climate and direct sunlight, use the detector sunshade.

- When considering process conditions. For example, butane and ammonia are usually heavier than air, but if released from a high temperature and/or pressurized production line, these gases will rise rather than fall.

- The detector should be placed slightly away from high-voltage components to allow the formation of aerosols. Otherwise, the leaked gas may pass through the detector at a high speed without being detected.

- Consider the convenience of functional testing and maintenance.

- The detector should be installed in position, and the detector should face down. This can effectively prevent dust or moisture from gathering in front of the detector, allowing the gas to enter the detector smoothly.

- When installing an open-circuit infrared device, make sure that the infrared beam is not permanently shielded or blocked. Can allow short-term obstruction by vehicles, on-site staff, birds, etc.

- Ensure that the open circuit equipment is installed on a stable and non-vibrating structure.

How is the effective detection range of a fixed gas detector defined?

The effective coverage horizontal plane radius of the combustible gas detector should be 7.5m indoors and 15m outdoors. Within the effective coverage area, a detector can be set. The distance between the toxic gas detector and the release source should not be greater than 2m outdoors and 1m indoors.

Where to download this fixed gas detector manual?

To protect the patented technical parameters, please contact us for a manual.

Other gas sensors

Monitoring hazardous gases in the surrounding environment is fundamental to ensuring workplace safety. Many gases, such as carbon monoxide, hydrogen sulfide, etc., are difficult to

Carbon dioxide is a gaseous compound produced by the reaction of carbon and oxygen. Its chemical formula is CO2. A carbon dioxide molecule consists of

We all know that the chemical properties of ozone are extremely active. Its energy when it is free produces strong oxidation in an instant, which

Carbon dioxide is one of the standards for measuring indoor air quality, but unlike other pollutants, carbon dioxide has no color or smell, and carbon

Why is a gas detector necessary? In the industrial production process, the leakage of flammable, toxic and harmful gases often occurs, which will cause serious

The portable ozone meter is an instrument that can be carried with you to detect ozone. Handheld ozone detector Technical Parameters: Range: 0-10ppm, 0-5% Accuracy:

Application areas: agricultural greenhouses, smart breeding, industry outside air temperature humidity sensor It adopts a wall-mounted high-grade enclosure with a protection grade of IP65, rain

Gas stations store and sell a large amount of gasoline and diesel during their operations. Compared with diesel, gasoline has strong volatility. It is easy