Measuring tilt angles is an important part of geometric metrology. The range of angle measurement is wide. According to the spatial position of the plane, it can be divided into: the horizontal angle (or azimuth angle) in the horizontal plane direction, the vertical angle (or inclination angle) in the vertical direction, and the spatial angle is the horizontal angle plus the vertical angle. An inclinometer is a front-end sensor that measures the size of an object’s inclination or depression relative to gravity. Here, we will discuss the different types of inclinometers, how they work, and what they are used for.

What is an inclinometer?

Inclinometers, also known as tilt sensors, are used to measure the inclination angle or deformation for fixed structures. As a detection tool, it is often used in bridge erection, railway laying, civil engineering, building safety and other places.

The inclinometer installation procedure depends on the field of application. It can be installed vertically to monitor cutting slopes or any movement of support walls and embankments. It can also be installed horizontally for foundation trenches and farmland leveling. Monitor and control flatness.

How the inclinometer works

Inclination sensors work by measuring acceleration. Inside a system, velocity cannot be measured, but its acceleration can be measured. If we know the initial velocity, we can calculate the linear velocity through integration, and then we can calculate the linear displacement. So it is actually an acceleration sensor that uses the principle of inertia. When the inclinometer is stationary, there is no acceleration in the lateral and vertical directions, so it only has the acceleration of gravity. The angle between the vertical axis and the sensitive axis of the sensor is the tilt angle.

What are the types of tilt sensors?

There are different types of tilt sensors. Every inclinometer system requires a combination of equipment and sensors to measure and collect data. According to different functions and principles, the classification of tilt sensors is also different.

A single-axis tilt sensor can only measure angular changes around one axis. Its measurement principle is based on Newton’s second law, which uses the principle of inertia to measure the acceleration of an object.

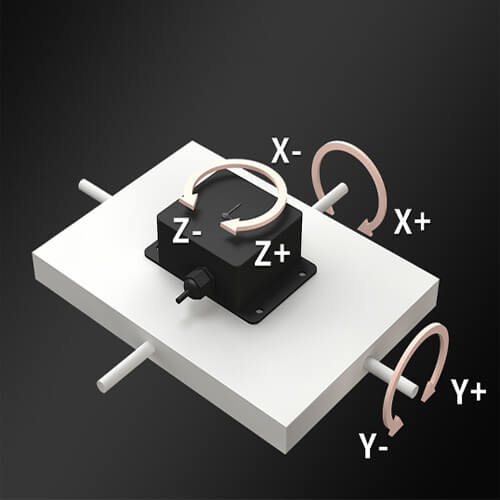

The dual-axis tilt sensor can measure the angular change in both the X-axis and the Y-axis. Comply with the inertial law and integral calculation method of object motion. The sensor consists of two sensing elements at a 90-degree angle to each other. Each has an output determined by its tilt angle from the vertical about an axis.

The difference between single-axis tilt sensor and dual-axis tilt sensor:

Depending on the installation method, the angles measured by the single-axis and dual-axis tilt sensors are also different. The dual-axis can measure the roll and pitch angles, while the single-axis can only measure the roll angle or pitch angle when it is installed horizontally. During installation, only the flip angle can be measured, and the pitch angle cannot be measured.

The inclined surface part of the dual-axis inclination sensor is a point or a line, while the single-axis can only be a line. For example, the inclination of the vertical wall takes the coincidence line of the wall and the foundation as the active part, and a single axis can be used at this time. In the process of slowly tipping a vertical rod, the contact point is the active part, so it needs to be measured with a dual-axis tilt sensor.

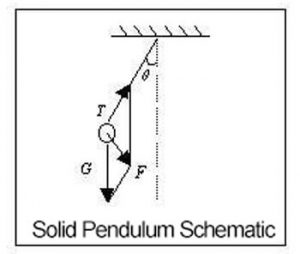

1. Solid pendulum tilt sensor

A force-balanced servo system is widely used in the design of solid pendulums. It consists of a pendulum, a cycloid, and a bracket. The pendulum is affected by the gravity G and the pendulum pulling force T, and the resultant external force is F=Gsinθ=mgsinθ. Among them, θ is the angle between the cycloid and the vertical direction. When measuring in a small angle range, it can be considered that F and θ have a linear relationship, and the strain-type tilt sensor is based on this principle.

2. Liquid pendulum tilt sensor

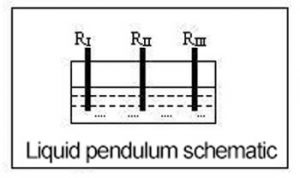

The principle of the liquid pendulum is that the glass shell has a conductive liquid, and there are three platinum electrodes connected to the outside. The three electrodes are parallel and equally spaced. When the housing is horizontal, the electrodes are inserted into the conductive liquid to the same depth. If an alternating voltage of equal amplitude is applied between two electrodes, an ionic current will be formed between the electrodes, and the liquid between the two electrodes is equivalent to two resistors RI and RIII. If the liquid pendulum is horizontal, then RI=RIII.

When the glass shell is tilted, the conductive liquid between the electrodes is not equal, and the immersion depth of the three electrodes in the liquid also changes, but the immersion depth of the middle electrode remains basically unchanged. When the immersion depth of the left electrode is small, the conductive liquid decreases, the number of conductive ions decreases, and the resistance RI increases. On the opposite pole, the conductive liquid increases, the number of conductive ions increases, and the resistance RIII decreases, that is, RI>RIII. Conversely, if the inclination directions are opposite, RI<RIII.

3. Gas pendulum tilt sensor

The “gas pendulum” inertial element is composed of a closed cavity, gas and hot wire. When the plane where the cavity is located is inclined relative to the horizontal plane or the cavity is subjected to acceleration, the resistance of the hot wire changes, and the change in the resistance of the hot wire is the angle q or a function of acceleration, and thus also has a pendulum effect. The change in the resistance of the heating wire is caused by the energy exchange between the gas and the heating wire.

The sensitive mechanism of the “gas pendulum” inertial device is based on the energy transfer in a closed cavity, in which there is a gas and a hot wire, and the hot wire is the only heat source. When the device is energized, the gas is heated. Convection is the predominant form in thermal energy exchange.

The difference between solid pendulum, liquid pendulum and gas pendulum:

They each have their own strengths. In the gravitational field, the sensitive mass of the solid pendulum is the pendulum mass, the sensitive mass of the liquid pendulum is the electrolyte, and the sensitive mass of the gas pendulum is the gas. The gas is the only movement in the sealed cavity, its mass is small, and the inertial force generated in the case of large impact or high overload is also small, so it has strong anti-vibration or impact ability. But the gas motion control is more complicated and the precision is not high.

The solid pendulum tilt sensor has a clear pendulum length and pendulum center, and its principle is the same as that of the acceleration sensor. The measurement range and accuracy are high. The liquid pendulum angle sensor is between the two, but the system is stable, and it is widely used in high-precision systems.

What are the applications of inclinometers?

- 1. The inclinometer is applied on the foundation trench leveling machine, which is used for the foundation trench and farmland ground leveling. Monitor and control flatness.

- 2. The inclinometer is applied on the paddy field grader for soil leveling. The paddy field leveling technology can save irrigation water and improve the utilization rate of fertilizers in the process of rice production.

- 3. The inclinometer is applied in the vehicle photoelectric tracking device. Install a dual-axis inclination sensor on the base of the photoelectric tracking device to monitor the levelness of the base. Ensure the high-precision work of the on-board photoelectric tracking equipment.

- 4. Inclinometer is used for urban pipeline robots.

- 5. The application of the inclinometer in the process of launching the ship.

- 6. The inclinometer is applied on the ship-borne water platform and is used for the base of the satellite tracking antenna to keep the antenna always in a horizontal state. Real-time control of the platform isolates the pitch and roll motion of the hull to keep the platform level.

- 7. The inclinometer is used to monitor and adjust the swing of the hook of a large ship.

- 8. Inclinometers are widely used in industrial inclination measurement and monitoring of dangerous buildings, protection of ancient buildings, bridge inclination measurement, tunnel monitoring, dam monitoring, drilling inclination control and other industries.

How to install the inclinometer?

There are certain skills in the installation of the inclinometer. Generally, the inclination sensor will have a built-in zero adjustment, so the user can set the zero adjustment button to realize the function of zeroing at a certain angle. Before installing the inclinometer, determine where you are going to install it and what angle and which plane you need to measure, eg in relation to a certain plane. When installing, fix the sensor on a certain plane, and use the zero button to realize the zero-clearing function before measurement, which is mainly to facilitate the reading of the angle and reduce unnecessary errors.