The key to the smart industry lies in the collection of data and information. Sensors are the nerve endings of the smart industry. They are used to collect data and provide basic data support for the construction of the smart industry. At the same time, with the rapid development of the Internet of Things, Industry 4.0, and intelligent manufacturing, application requirements are getting higher and higher. Smart sensors that collect the most initial data are rapidly upgrading and iterating, driving the intelligent transformation of industrial Internet terminals. “Industrial Sensor 4.0” or the era of industrial sensors is booming. It ranges from industrial process sensing and factory automation, from microcontrollers and wired or wireless connections to cloud servers.

Smart sensors used for industrial

In industrial automation, sensors play a vital role in making production intelligent and automated. These allow people to monitor, analyze, and process various changes that occur on the industrial manufacturing site, such as changes in temperature, motion, pressure, altitude, external, and security.

Almost every process or environmental condition has a suitable sensor type. The smart sensor integrates signal conditioning, MEMS technology, and firmware, so as to meet the easy-to-use and low-cost perception needs of industrial design engineers, and greatly reduce the development burden of design engineers.

Types of industrial sensors

The following are the various types of industrial sensors commonly used in automation:

- Temperature Sensors

- Pressure sensors

- Level sensors

- Infrared sensors

- Proximity sensors

- Smoke sensors

- Optical Sensors

- MEMS Sensors

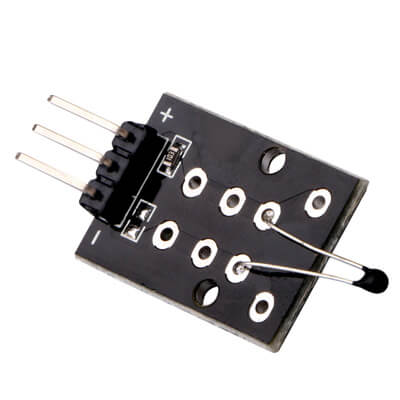

Temperature sensors

In industrial production, temperature is the most frequently measured physical parameter, and various sensors can be used for measurement. A temperature sensor is a device that collects information about temperature from the environment and converts it into specific values. Among them, digital temperature sensors and temperature and humidity sensors are most commonly used in industrial automation.

The digital temperature sensor sampling card has a ten-digit dual-channel successive approximation A/D converter and a standard RS-232 or 485 communication interface. The product adopts a filtering method that combines recursive average digital software filtering and hardware circuit filtering to minimize external interference to sampling, with high full-scale accuracy, strong stability, good consistency, and fast response.

The temperature and humidity sensor is an integration of a temperature sensor and a humidity sensor. The temperature and humidity probes are used as temperature measurement components to collect temperature and humidity signals, and after circuit processing, they are converted into current signals or voltage signals that are linearly related to temperature and humidity. It can also be directly passed through the main control chip. Perform interface output such as 485 or 232.

Application of temperature sensors: Temperature sensors are widely used in various industries, such as medical industry, industry, food industry, hydropower station, petrochemical industry, metallurgy industry, printing, and dyeing pharmaceutical industry and other industries have applications.

Pressure sensors

The pressure sensor is a device that can sense the pressure signal and convert the pressure signal into a usable output electrical signal according to a certain rule. The pressure sensor is usually composed of a pressure sensitive element and a signal processing unit.

Pressure sensors are used to monitor pipelines and send leaks or abnormal alarms to the central computing system to remind supervisors that maintenance and repairs are needed.

Application of pressure sensors: Pressure sensor is the most commonly used sensor in industrial practice. It is widely used in various industrial automation environments, including water conservancy and hydropower, railway transportation, intelligent buildings, production automation, aerospace, military, petrochemical, oil wells, Power, shipbuilding, machine tools, pipelines and many other industries. Another medical pressure sensor.

Level sensors

Level sensors are a device used to monitor, maintain and measure the level of liquids (sometimes solids). Once the liquid level is detected, the sensor converts the sensed data into electrical signals. The liquid level sensor is a device used to determine the liquid level flowing in an open system or a closed system.

Liquid level measurement can be divided into continuous measurement and point level measurement. The continuous liquid level sensor is used to accurately measure the liquid level, but the measurement result is correct. The point level sensor is used to determine whether the liquid level is high or low.

Application of level sensors: The level sensor is mainly used in the manufacturing and automobile industry, but it can also be found in many household appliances, such as ice makers in the refrigerator, washing machines, and it is necessary to prevent the liquid level from being too high to overflow too much. The water heater needs to automatically replenish water when the liquid level of the internal water tank is too low, and the toilet needs to keep water in the water tank for leakage identification or liquid level identification.

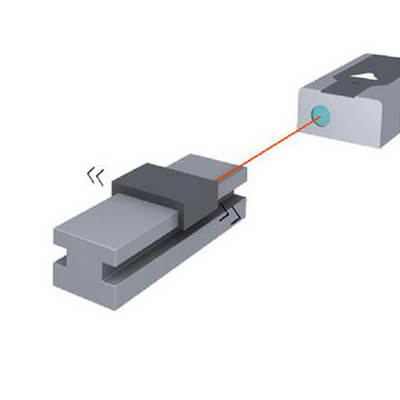

Infrared sensors

An infrared sensor is a device that uses infrared to process data. Infrared is also called infrared light. It has properties such as reflection, refraction, scattering, interference, and absorption. Any substance, as long as it has a certain temperature (above absolute zero), can radiate infrared rays.

The infrared sensor is not in direct contact with the measured object during measurement, so there is no friction, and it has the advantages of high sensitivity and fast response. The infrared sensor can control the operation of the drive device. Infrared sensors are often used for non-contact temperature measurement, gas composition analysis, and non-destructive testing.

Application of infrared sensors: Infrared sensors are widely used in the fields of medicine, military, space technology, and environmental engineering. Infrared sensors integrated with industrial IoT solutions are also used in other industries.

Proximity sensors

The proximity sensor is a device with the ability to perceive the proximity of an object. It uses the sensitive character of the displacement sensor to recognize the proximity of the object and outputs the corresponding switch signal. The proximity sensor can perform non-contact sensing detection, so it will not wear and damage the detection object, and there is no spark or noise. Since it is a non-contact output mode, it has a long service life and hardly has any influence on the service life of the contact. The proximity sensor is different from other detection methods in that it is suitable used in a water and oil environment, and it is hardly affected by the stains and water and oil of the detection object.

Among them, the proximity sensor itself can only detect metal objects at close range and without contact. The biggest feature of the variable-range elastic rod device is that it can overload the sensing range of the contact. Spring-loaded pistons, probes, and buttons are generally used to contact the product and then detect whether the product is in place, have accurate positioning, and verify the product being tested.

Applications of proximity sensors: Proximity sensors are mainly used to detect the displacement of objects, and are widely used in aviation, aerospace technology, and industrial production. In daily life, such as hotels, restaurants, garages, automatic doors, automatic hot air blowers have applications. In terms of security and anti-theft, such important places as data files, accounting, finance, museums, and vaults are usually equipped with anti-theft devices composed of various proximity switches. In the measurement technology, the measurement of length and position; in the control technology, such as the measurement and control of displacement, velocity, and acceleration, there are also a large number of proximity switches for users.

Smoke sensors

The smoke sensor can detect a large amount of smoke generated during a fire and send out an alarm signal in time. The detector adopts MCU control, which can intelligently judge the smoke generated during the fire and alarm. The smoke sensor is an indispensable sensor in a flammable and explosive industrial production environment. When smoke sensors are integrated with industrial IoT solutions, even the slightest gas leak or minor fire can be reported to the relevant team, thereby avoiding major disasters.

Application of smoke sensors: Widely used in HVAC, construction site monitoring, and industrial units with the high possibility of fire and gas leakage.

Optical sensors

The optical sensor is based on the optical principle for measurement. It has many advantages, such as non-contact and non-destructive measurement, almost no interference, high-speed transmission, and remote control. It mainly includes optical sensors and instruments such as general optical measuring instruments, laser interferometers, gratings, encoders, and fiber optics. In the design, it is mainly used to detect whether the target object appears, or to perform various industrial automation motion detection.

Application of optical sensors: Widely used in industrial automation places such as telecommunications, elevators, construction, healthcare, and security systems.

MEMS sensors

MEMS sensor is a new type of sensor manufactured using microelectronics and micromachining technology. Compared with traditional sensors, it has a small size, low power consumption, high reliability, and is suitable for mass production. The MEMS motion sensor is integrated with the ZigBee wireless technology to perform anthropomorphic interactions while working with the machine. The feature size on the order of micrometers allows it to perform functions that cannot be achieved by some traditional mechanical sensors.

Application of MEMS sensors: As a key device for obtaining information, MEMS sensors have played a huge role in the miniaturization of various sensing devices. They have been used in space satellites, launch vehicles, aerospace equipment, aircraft, various vehicles, and special It has been widely used in the fields of medicine and consumer electronics.

Conclusion:

As the entrance to the information collection, sensors are the “heart” of the Internet of Things, smart industries, and smart devices. The realization and development of the Industrial Internet are inseparable from the wide application of sensors and technological innovation. However, on the other hand, the Industrial Internet has also brought a huge market for the development of sensors. Industrial Internet and sensor development can be described as complementary.

Blogs

8 Best Industrial Gas Leak Detectors of 2021

Why is a gas detector necessary? In the industrial production process, the leakage of flammable, toxic and harmful gases often occurs, which will cause serious

Smart Farming: IoT In Agriculture

What is smart farming? Smart farming is the application of Internet of Things technology to traditional agriculture, using sensors and software to control agricultural production

How To Choose Air Quality Monitors In Different Places?

What is an air quality monitor? An instrument used to detect air quality can be called an air quality monitor. However, due to the extensive

Anemometer: Types, Advantages, Disadvantages

Table of Contents What is an anemometer? An anemometer is an instrument that measures the velocity of air, sometimes called a wind sensor. The earliest

Water Level Sensor | What, How, Where, Benefits, Types

Table of Contents What is a water level sensor? The water level sensor is a device that measures the liquid level in a fixed container

Temperature And Humidity Sensor Definition, Calibration, And Top10 Best Choose

What is temperature and humidity sensor? Temperature and humidity sensors refer to equipment that can convert temperature and humidity into electrical signals which can be

Weather Station Installation And Buying Guide

Table of Contents Do you know where to mount weather station? The weather station should be installed as far as possible on the open ground