What is a tipping bucket rain gauge?

A tipping bucket rain gauge is one of the most standard sensor used for weather station applications. It is consists of a funnel that collects and channels the precipitation into a small seesaw-like container. After a pre-set amount of precipitation falls, the lever tips, dumping the collected water and sending an electrical signal.

Tipping bucket rain gauge function

The function of the tipping bucket rain gauge sensor is generally divided into the rain port part and the metering part. The instrument collects rain through the rain-bearing part, enters the tipping bucket in the measuring part for measurement, and outputs a measurable physical quantity signal.

The standard tipping bucket rain gauge on the weather station has an inner diameter of φ200mm for the rain-bearing opening, and the edge of the rain-bearing opening is blade-shaped, and the blade angle should be within the range of 40°~45°. Use anti-shock stainless steel material to prevent long-term use and deformation. The inner wall is smooth and free of blisters. Defects such as burrs, bruises, and leakage. The depth of the inner wall of the rain-bearing vent should not be less than 100mm to ensure that the rainwater entering the rain-bearing vent will not splash out.

If you have questions about buying a rain gauge, you can consult our professional technicians How Does A Tipping Bucket Rain Gauge Work?

Rain gauge measurement accuracy

When the rainfall intensity changes within the range of 0.01mm/min~4mm/min, the sensor accuracy is shown in the chart:

| Accuracy class | Tipping bucket measurement error (Eb) |

|---|---|

| Ⅰ | ≤±2% |

| Ⅱ | ≤±3% |

| Ⅲ | ≤±4% |

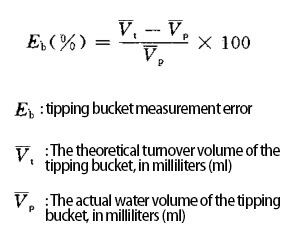

The error caused by the tipping bucket measurement is the tipping bucket measurement error, and the error is calculated according to the formula below, and the test condition is indoor manual dripping.

Tipping bucket rain gauge calculations

How to calibrate tipping bucket rain gauge?

In order to facilitate customer operation and reduce customer troubles during installation and use. Renke’s engineers designed the rain gauge calibration method to be very simple and easy to operate. After you receive the rain gauge, first unscrew the three screws at the bottom of the device, remove the stainless steel outer cylinder, and cut off the cable tie that secures the tipping bucket (as the picture shows). When the dome nut is kept in an unlocked state, just use two hands to adjust the height of the nut in the red circle to make the bubble in the horizontal bubble centered, then lock the dome nut (as the picture shows), check again, and Adjust whether the bubble of the horizontal bubble on the tipping bucket bracket is in the middle position. Then install the outer cylinder, the calibration of the rain gauge is completed.

Rain gauge types

The four commonly used rain gauge types are graduated cylinder rain gauge, tipping bucket rain gauge, siphon rain gauge, and weighing rain gauge. The measurement principle differs depending on the different applications. But the purpose is the same.

A graduated cylinder rain gauge (also called manual rain gauge) is a simple and inexpensive instrument to measure rainfall, but people have to wait until the rain is over to read the value. This is a test of the patience of the user and also requires Manual data calculation, this rain gauge may be accurate and reliable. If it takes a long time to record data once, evaporation in a warm environment has also become a problem that affects accuracy.

The tipping bucket rain gauge is the most commonly used instrument for measuring rainfall in weather stations. After the rainwater is collected at the top rain port, it passes through the funnel and enters a small seesaw-type bucket. After a certain amount of water is collected, the bucket will tip over, and the bucket on the other side will quickly move to an appropriate position to continue collecting rainwater. Usually, every time 0.2mm (or 0.5mm) of rainwater is collected, a pulse signal is output. The monitor can calculate the number of these pulse signals to estimate the total precipitation in a given time. In a windy environment, pay attention to cleaning up the debris at the rain-bearing opening, such as leaves, insects, and waste paper.

The tipping bucket rain gauge is currently the most commonly used rain gauge with high accuracy. Renke has released a new all-stainless steel rain gauge with a beautiful appearance, higher measurement accuracy, and long service life.

Siphon rain gauge is an instrument that automatically records the amount, intensity change, and starts and ends the time of liquid precipitation. It consists of four parts: rain receiver, siphon, self-recording, and shell. When the water receiver will collect the precipitation, it enters the float chamber through the funnel duct, and the float rises with the increase of the injected rainwater and drives the self-recording pen to draw a curve on the recording paper on the drum with the clock. The ordinate on the recording paper represents the rainfall, and the abscissa represents the time. The curve recorded on the recording paper is a cumulative curve, which not only represents the size of the rainfall, but also the change of the rainfall process. The slope of the curve represents the rainfall intensity, distinguished by the siphon rain gauge The rate is 0.1mm and the rain intensity adapts to the range of 0.01-4.Omm/min. But the disadvantage is that generally only 10mm of rain can be accumulated in the float chamber. When the rain reaches 10mm, the water must be drained. The precipitation during the emptying will also cause errors, and the siphon is prone to failure and requires frequent verification.

A weighing rain gauge refers to a device that records rainfall by weighing rainwater captured in a container. The weighing self-recording rain gauge can continuously record the weight of the precipitation on the rain cup and stored in it. The recording method can use a mechanical clockwork device or a counterweight system to record the weight of the total precipitation, and it can record the mixed precipitation of snow, hail, rain, and snow. Pressure errors and vibration errors caused by wind, non-horizontal installation errors, and debris falling into the weighing pan are unsolvable errors and must be maintained frequently.

Most weighing rain gauges must be cleaned manually by the staff, and in winter weather, the weighing pan is easy to freeze. In hot climates, they are susceptible to large evaporation errors, so oil is usually added to form a thin oil layer on the surface of the stagnant water to limit evaporation. In order to obtain usable rainfall data, it is necessary to perform a large amount of post-processing on the data of the weighing rain gauge. This operation is laborious and laborious and is a source of potential errors.