What is a light sensor?

A light sensor is a device that is sensitive to light and can detect light and convert it into an electrical signal. It can measure the intensity, wavelength, frequency or direction of light.

How do light sensors work?

The light sensor working principle is based on the photoelectric effect. The sensor uses photosensitive materials that can respond to the presence of light. These materials can be semiconductors, photoconductive materials, or photovoltaic materials. When light hits the photosensitive material, its electrical properties change. This change can manifest as a variation in resistance, the generation of current, or a change in voltage. The sensor then converts this change into an electrical signal.

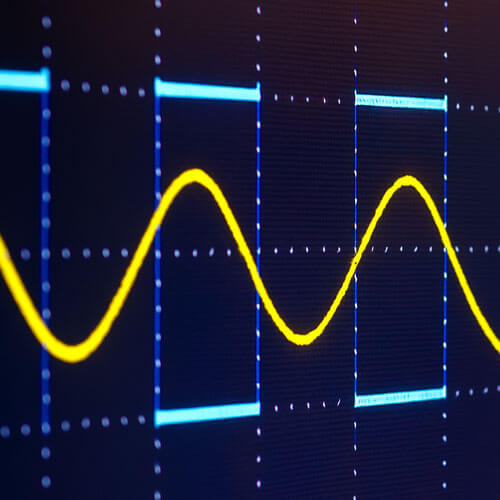

The electrical signal generated by the light sensor is usually very weak and needs amplification. This is achieved through an internal amplifier within the sensor. The amplified signal can then be further processed to obtain useful information, such as light intensity or wavelength. The processed signal is then output in a form that can be read by other electronic components or systems. Depending on the application requirements, this output can be in the form of an analog signal (continuous signal) or a digital signal (discrete steps).

Types of light sensors

Light sensor is a general term for all optical sensors. It is a broad term that includes many types of sensors. Each type has unique functions and uses. We mainly introduce four main types of light sensors:

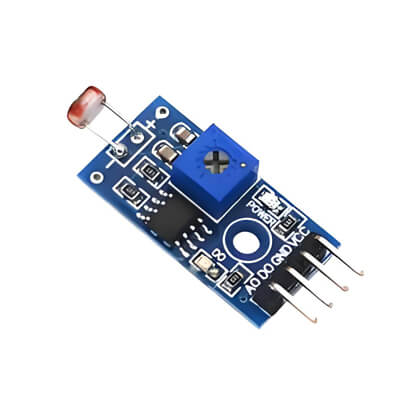

Photoresistor sensors are sensitive to visible light wavelengths, including infrared and ultraviolet wavelengths. When exposed to light, the resistance value of the measuring unit changes, and the change value is proportional to the light intensity. The simplest electronic device in a photosensitive sensor is a photoresistor, which can sense the change in light and output a weak electrical signal. After amplification and processing by a simple electronic circuit, it can control the automatic switching of LED lamps.

Photoresistor sensors are widely used in automatic control and household appliances, such as the brightness of televisions and the automatic exposure of cameras. Photoresistor sensors are cheap and simple in structure, but have slow response speed and low accuracy.

2. Photodiode sensors

When light strikes the PN junction of a photodiode, the light is absorbed and excites the production of electron and hole pairs, which generates an electric current, which is the working principle of a photodiode sensor. The output signal of the photodiode is proportional to the light intensity, and the signal conversion and measurement can be carried out by amplification and processing circuits.

Photodiode sensors are commonly used in automation systems and industrial controls. For example, they can be used for component detection on automated assembly lines, label detection on packaging machinery, and robot positioning. It has a faster response time and higher accuracy than photodiode sensors. However, photodiode sensors are more expensive than photoresistive sensors.

3. Fiber-optic sensors

The working principle of the fiber optic sensor is to send the incident light source into the modulator through the optical fiber. After being processed by the modulator, the intensity, wavelength, frequency, phase, etc. of the light changes to become a modulated optical signal, thereby obtaining a specific value.

Fiber optic sensors have good electrical insulation performance, strong anti-interference ability and high sensitivity. Easy to connect with computer. It can be used for telephone, network broadband and other digital model transmission. Widly used for automation equipment product positioning, counting, identification.

4. Photoelectric effect sensors

The principle of this sensor is based on the photoelectric effect, the change of light into the change of light signal, and then with the help of photoelectric components to further convert the light signal into an electrical signal. It can detect non-electrical physical quantities that directly cause changes in the amount of light, such as light intensity, light intensity, radiation temperature measurement. It can also detect other non-electrical quantities that can be converted into changes in the amount of light, such as the diameter of parts, surface roughness, and the shape of the object.

Photoelectric sensors have the characteristics of non-contact, fast response, reliable performance, etc., so they are widely used in industrial automation devices and robots.

Measuring range of light sensor

For outdoor environments, the light intensity can reach 60,000 to 100,000 lux in direct sunlight in summer. 1,000 to 10,000 lux outdoors without the sun. 100 to 550 lux in bright summer indoors, 0.2 lux at night under a full moon.

For indoor environments, incandescent lamps can emit about 12.56 lux per watt, but the value varies with the size of the bulb. Small bulbs can emit more lumens, large bulbs less. The luminous efficiency of fluorescent lamps is 3 to 4 times that of incandescent lamps.

Where is the light sensor installed?

The light sensor is best installed in the center of the measurement area, away from any objects that reflect or scatter light. At the same time, ensure that there is no obstruction at the installation point to prevent measurement errors. Avoid locations close to electric lights or other light sources as much as possible, such as near table lamps, doorways, windows, etc.

Installation height selection

For indoor light sensors, the installation height is generally around 2.5-3m. If the detection range is larger, the installation height should be increased appropriately. For outdoor light sensors, the installation height should be between 2.5-4m, and there is no obstruction around.

Avoid strong light

When installing the light sensor, keep it away from direct exposure to artificial light or direct sunlight, such as incandescent lamps, LED lamps, and solar lamps. These light sources will directly affect the accuracy of the measurement data.

Installation Angle

When installing the light sensor to ensure that its installation angle perpendicular to the ground to ensure the best observation effect. At the same time, the installation needs to pay attention to avoid the sensor tilt, resulting in increased error.

What are the applications of light sensors?

The role of the light sensor is to measure the intensity and change of the surrounding light and convert it into an electrical signal output to reflect the surrounding light conditions. It can be used in a variety of application scenarios to realize automatic control, lighting regulation, environmental monitoring and other functions. The following are the main applications of light sensors:

Automatic lighting control: Automatically turn on indoor lighting and adjust the light intensity at night or on cloudy days. Automatically reduce or turn off indoor lighting during daytime or sunny seasons. During stage performances, control the color and direction of the lights on the stage to change as the performance progresses. All of these are inseparable from light sensors. Use the light sensor with other home automatic sensors (such as the temperature and humidity sensor) to create an automated living environment.

Weather monitoring: Light sensors are an important part of professional environmental weather stations. By installing light sensors on weather stations in remote areas, researchers can keep track of the light conditions at the monitoring points, such as sunny, cloudy or foggy days.

Temperature control systems: Light sensors can automatically adjust curtains, blinds or air-conditioning units according to the difference between indoor and outdoor light to provide a more comfortable living environment.

Agricultural production: Light sensors are components of greenhouse lighting systems. They monitor the amount of light in the greenhouse and control the timely opening or closing of the top sunshade to ensure that plants receive sufficient light to increase crop yields.

Industrial automation: Light sensors are often used to monitor the brightness and color of light sources to confirm the precise positioning and location of robots or assembly lines based on light perception. For example, in automated smart warehouses, light sensors can monitor light to ensure safety and clear visibility inside delivery vehicles.

Security systems: Light sensors can also be used in security systems such as fire alarm and intrusion detection. By monitoring changes in light, the sensor can detect abnormal events and trigger an alarm.