Carbon dioxide is one of the standards for measuring indoor air quality, but unlike other pollutants, carbon dioxide has no color or smell, and carbon dioxide cannot be detected by the senses alone. You can be sure that the only way to know the indoor carbon dioxide level is through co2 sensors.

What is a carbon dioxide sensor?

The carbon dioxide sensor is a gas detection instrument, which is mainly used to measure the content of carbon dioxide in the air. When the content of carbon dioxide is too much or too little, the carbon dioxide sensor will send out an alarm, and people will take corresponding measures in time according to its prompts. The air quality meets people’s requirements. This kind of device is mainly used in daily production and life and has played an important role in creating a good atmospheric environment for people. The application range of carbon dioxide sensors is not extensive, the application areas include the beer industry, carbonated beverage industry, coal industry, agricultural planting industry, agricultural breeding industry, and people’s daily life.

Types of co2 sensors

There are many types of co2 sensors on the market. To be able to correctly choose the most suitable sensor for you, you should understand the advantages and disadvantages of each type of sensor before deciding which sensor to use. The following lists four common types in the market according to the working principle of carbon dioxide sensors.

- Non-dispersive infrared co2 sensors

- Electrochemical co2 sensors

- Semiconductor co2 sensors

- Catalytic combustion co2 sensors

1. Non-dispersive infrared co2 sensors

The non-dispersive infrared carbon dioxide sensor is made based on the working principle that the absorption spectrum of gas varies with different substances. The carbon dioxide sensor element controls the internal infrared lamp to emit infrared light of a fixed band through the drive circuit. After the absorption of the gas to be measured, the amplitude of the infrared light changes, and then the concentration of the gas to be measured is calculated by detecting the change, that is, the output of the sensor element The signal is filtered, amplified, and ADC collected and converted, and then input to the microprocessor. The microprocessor system performs corresponding temperature and pressure compensation processing according to the collected temperature and pressure and finally calculates the carbon dioxide concentration value to be measured and outputs it to the display equipment.

Advantages: High sensitivity, fast analysis speed, good stability, and long service life.

Disadvantages: NDIR sensor has high power consumption, complicated structure, software, and hardware, and the price is relatively expensive.

2. Electrochemical co2 sensors

The electrochemical carbon dioxide sensor is a type of chemical sensor that converts the concentration (or partial pressure) of carbon dioxide into an electrical signal through an electrochemical reaction. According to the detected electrical signal, the electrochemical type is divided into potential type, current type, and capacitive type. According to the electrolyte form, there are liquid electrolytes and solid electrolytes. From the 1970s until now, solid electrolyte carbon dioxide sensors have always been the focus of scientific research workers. The principle of the solid electrolyte carbon dioxide sensor is that the gas-sensitive material generates ions when passing through the gas, thereby forming an electromotive force, and measuring the electromotive force to measure the gas volume fraction.

Advantages: fast measurement speed, simple operation, and low cost.

Disadvantages: short life, easy to aging, and the sensor is easy to “drift” or lose accuracy. The measurement accuracy is easily disturbed by other gases.

3. Semiconductor co2 sensors

The semiconductor gas sensor is made by using the oxidation-reduction reaction of the gas on the semiconductor surface to change the resistance value of the sensitive element. When the semiconductor device is heated to a stable state and is adsorbed when the gas contacts the semiconductor surface, the adsorbed molecules first diffuse freely on the surface of the object and lose their movement energy. Some of the molecules are evaporated, and the other part of the remaining molecules is thermally decomposed and adsorbed on the object. surface. When the work function of the semiconductor is less than the affinity of the adsorbed molecules, the adsorbed molecules will take away electrons from the device and become negative ions adsorbed, and the surface of the semiconductor presents a charge layer. If the work function of the semiconductor is greater than the dissociation energy of the adsorbed molecules, the adsorbed molecules will release electrons to the device and form positive ion adsorption. It is a gas sensor made of the change of the capacitance-voltage characteristic of the mos diode and the change of the threshold voltage of the mos field-effect transistor.

Advantages: fast response, strong environmental resistance, stable structure

Disadvantages: easily affected by temperature and humidity, usually used for higher and less common CO2 concentrations, other substances in the air will affect the reading

4. Catalytic combustion co2 sensors

The catalyst co2 sensor is a carbon dioxide sensor with a catalyst as the basic element. It uses the catalyst coating on the surface of a specific type of resistor. At a certain temperature, flammable gas is catalytically burned on the surface as the principle of carbon dioxide sensor. Therefore, people call this carbon dioxide sensor a thermal combustion sensor.

Advantages: accurate measurement, fast response, and long life.

Disadvantages: The range of selectable gases is small.

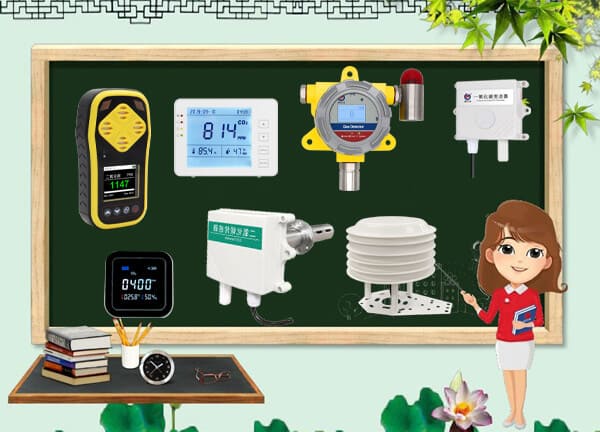

7 types of co2 sensors used in different places

In addition to the different working principles, the appearance and functions of the co2 sensors used in different places are also different. Here are 7 kinds of co2 sensors used in different places.

It is small and practical, wireless and portable, and powerful. It is an indoor carbon dioxide detector that can measure the microclimate of the bedroom related to life and work-humidity, carbon dioxide, and temperature. The exquisite electronic screen shows what should be improved to improve the current environmental quality.

For offices that want to increase the long-term productivity of the team, this relatively light device is a good choice. It is cheap, easy to operate, and no wiring is required.

This wall-mounted CO2 sensor is highly protective professional equipment used to measure the air quality in almost all places where large amounts of CO2 are usually produced: schools, office buildings, hotels, greenhouses, and factories. Wide measurement range, 0-5000ppm or 0-10000ppm. The overall shell is waterproof and can be used in harsh environments. Once installed, it can work normally for 5-10 years.

It adopts rs485 or analog output, the signal is stable, and the measurement is accurate.

This portable CO2 detector is a standard configuration for professional gas detectors, and it can be used to measure the CO2 concentration in different places and locations. High mobility. Using rechargeable batteries, it can work continuously for 8 hours. The display shows the readings in a very easy-to-understand way. The alarm function can come in handy to notify when CO2 reaches or reaches a set limit.

It is also a fire-proof and explosion-proof gas detector, which is mainly installed inflammable and explosive places for testing. The overall appearance is made of high-strength stainless steel, which is waterproof and dustproof. After installation, the measurement data of the current equipment can be viewed remotely, effectively reducing the occurrence of dangerous accidents and ensuring the safety of the property. This explosion-proof co2 detector is mainly used in industrial environments.

For customers who need to monitor the outdoor CO2 concentration for a long time, what is the most important? The answer is: rain and snow, high and low-temperature resistance, and radiation resistance. This requires that the sensor housing can not only ensure gas flow but also be waterproof and anti-corrosion. In order to meet the needs of these users, we have developed an outdoor co2 sensor with IP68 protection level, which can be installed outdoors for a long time and view data remotely. The practicality is very high, it is recommended to buy.

When we want to measure the air quality of the overall environment, we are not only measuring a single element, we need a sensor that can measure multiple air quality elements at the same time, and the elements will not interfere with each other. In addition to measuring co2, our AQI sensor can also add other elements, such as: temperature, humidity, atmospheric pressure, light, CO, NH3, CH4, O2, formaldehyde, TVOC, O3, SO2, NO2, H2, etc., a The complete AQI sensor can measure 11 elements and is powerful. You only need one AQI sensor to complete the work that requires multiple gas detectors together.

This duct-type co2 sensor is a device for measuring the concentration of co2 in the tube. The sensor is located in the stainless steel metal pipe at the end. By drilling a hole in the tube, inserting the stainless steel probe into the tube and fixing it to measure the CO2 in the tube for a long time. The special appearance setting can effectively adapt to the special environment. Accurate measurement and easy operation.