Table of Contents Water leak detection is designed to detect and repair leaks in pipes, equipment or building structures in

Industrial Water Leak Detector

This industrial water leak detector adopts unique AC detection technology, which effectively avoids the problem of water leakage sensitivity decreased due to oxidation of the immersed electrode for a long time. We offer 485 output and switch dry contact output. It can be connected to the on-site PLC, industrial control instrument, configuration screen, or configuration software. The maximum distance of the external leakage electrode can reach 30 meters, the external water leak rope of up to 30 meters. This is an industrial water immersion sensor.

- Model: RS-SJ-*-2-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: USD 23.10

About - Water Leak Detector

Wired water leak sensor description

Our company uses alternating current to collect the inductance parameters of stagnant water to accurately distinguish whether water is immersed, and can even distinguish between pure water and tap water (the tap water is the default detection object, if you want to detect pure water, please give special instructions). Because of the use of alternating current detection, the electrode will not produce electrophoretic polarization even if it is immersed for a long time. It does not rely on special electrodes to achieve long life and reliable detection. —This technology is our company’s patent and has been authorized by the Patent Office. Our company reserves the right to pursue legal liabilities for any counterfeiters.

In addition to this industrial water leak detector, we also have a positioning water leak detector that can display the location of the water leak in real-time when it detects a water leak.

Water leak detector parameters

Power supply: DC10-30V

Max. power consumption:

Relay output: 1.2W

RS485 output: 0.4W

Detection object: Tap water, purified water

Operating temperature: -20℃~+60℃, 0%RH~80%RH

Output signal:

Relay output: Normally open contact

RS485 output: Modbus-RTU protocol

Application - Water Leak Detector

The water leakage sensor is widely used in communication base stations, hotels, restaurants, computer rooms, libraries, archives, warehouses, equipment cabinets, and other places where water accumulation is required to alarm.

Water leak detector wiring

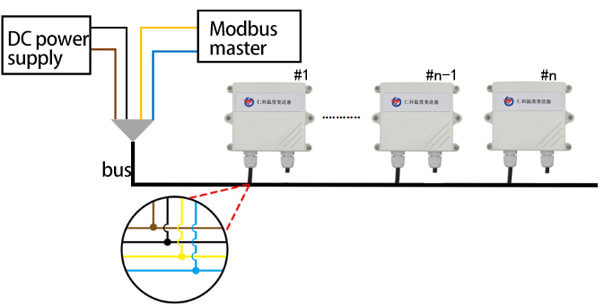

1. Power supply and 485 signal wiring

Wide-voltage power input can be 10~30V. When wiring the 485 signal line, pay attention to the two wires A and B not being reversed, and the addresses of multiple devices on the bus cannot conflict.

2. Relay interface wiring

The standard equipment is equipped with 1 relay output, and the two outgoing wires are normally open contacts.

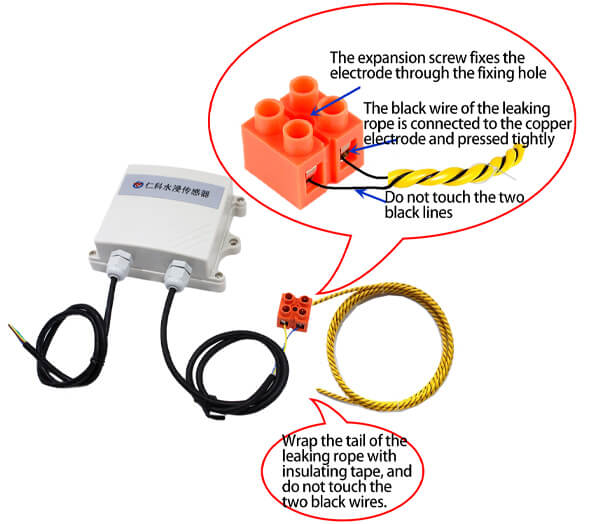

3. Use of leaking rope

Customers who buy our line-type water leakage sensor, please pay attention when connecting the leaking rope. The black line is the water leakage sensor line, and the yellow line is the support frame. The black sensor lines at both ends of the leaking rope should not touch each other.

FAQ- Water Leak Detector

Use alternating current to collect the inductance parameters of stagnant water to accurately distinguish whether flooding occurs.

First find out the leaking location, then close the main valve, repair the leaking place, clean up the stagnant water, and finally open the main valve.

You can continue to use the sensor after cleaning up the accumulated water of the water leak sensor.

To protect the patented technical parameters, please contact us for a manual.

Possible reasons:

- The computer has multiple COM ports and the selected port is incorrect.

- The device address is wrong, or there are devices with duplicate addresses (the factory defaults are all 1).

- The baud rate, check method, data bit and stop bit are wrong.

- The host polling interval and waiting response time are too short, and both need to be set above 200ms.

- The 485 bus is disconnected, or the A and B wires are connected reversely.

- If the number of equipment is too much or the wiring is too long, the power supply should be nearby, add 485 boosters, and add 120Ω terminal resistance at the same time.

- The USB to 485 drivers is not installed or damaged.

- The equipment is damaged.

Other popular sensors

Related blogs

Long-term rainfall and melting snow have raised water levels and flooded city roads, causing flooding. Frequent and extreme flooding is

Table of Contents Smart buildings are the product of the development of modern science. The smart building system is mainly

Natural disasters such as floods and heavy rains pose threats to lives and property around the world. Without a proper

The key to the smart industry lies in the collection of data and information. Sensors are the nerve endings of

Table of Contents Modern companies are placing an increasing emphasis on the value of collected data. As a result, central

Table of Contents Have you or your friend experienced a broken water pipe, water accumulation in the kitchen or bathroom?

Table of Contents What is IoT? IoT is the “Internet of things“. It is an extended and expanded network based

Table of Contents What are industrial sensors and actuators? Industrial sensors are devices that can convert physical or chemical quantities

The application of sensors in life is the smart home system. The smart home system is composed of sensors, actuators,