Table of Contents What is an infrared sensor? Infrared sensor is a sensor that uses infrared rays to measure temperature, analyze gas composition or perform

Non Contact Infrared Temperature Sensor

What is an infrared temperature sensor? The infrared temperature sensor can calculate the surface temperature of the object by measuring the intensity of the infrared radiation emitted by the target. Non-contact temperature measurement is the biggest advantage of infrared thermometers, allowing users to easily measure targets that are difficult to approach or move. We offer infrared temperature sensor RS485 and infrared temperature sensor 4 20ma two types.

- Model: RS-WD-HW-*-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: $52.4~$167.7

About Infrared Temperature Sensor

Renke infrared temperature sensors offer a wide measurement range from -30℃ to 1200℃. This industrial-grade infrared temperature sensor is designed for measuring the surface temperature of both moving and stationary objects. It operates using non-contact technology by detecting infrared radiation emitted from the target within the 8μm to 14μm wavelength range, and accurately calculates the surface temperature based on this data. It is ideally suited for industrial applications such as manufacturing, steel production, and food processing.

Description

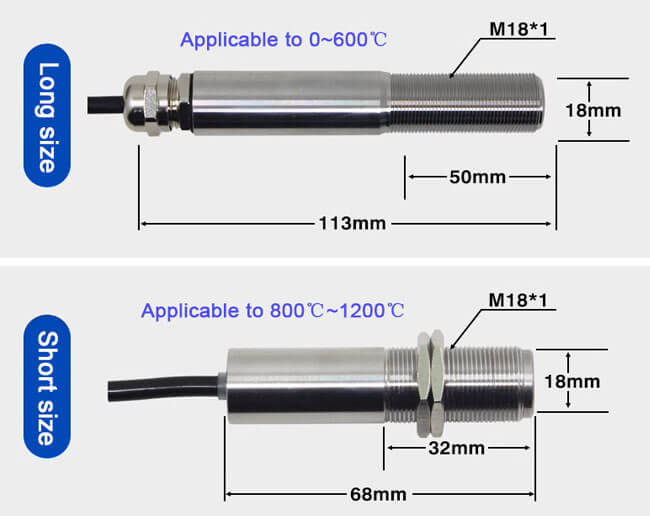

The RS-WD-HW-*-EX is an integrated infrared temperature sensor that combines the sensing element, optical system, and electronic circuitry within a durable stainless steel housing. The standard threaded interface on the stainless steel enclosure allows for quick and easy installation on-site.

This infrared temperature sensor is compatible with a variety of optional accessories—such as digital displays, laser aiming devices, cooling jackets, and adjustable mounting brackets—to adapt to different industrial measurement environments. With a wide measurement range (0–1200℃), high accuracy, and user-friendly design, it is an outstanding industrial-grade infrared temperature sensor.

Features

RS-WD-HW-*-EX IR temperature sensor can calculate the surface temperature without touching the object, and can measure the temperature of moving objects. The sensor has built-in temperature compensation with high accuracy. The shell is made of stainless steel, which is waterproof and dustproof. In the same environment, our infrared temperature sensor is more stable than other products on the market.

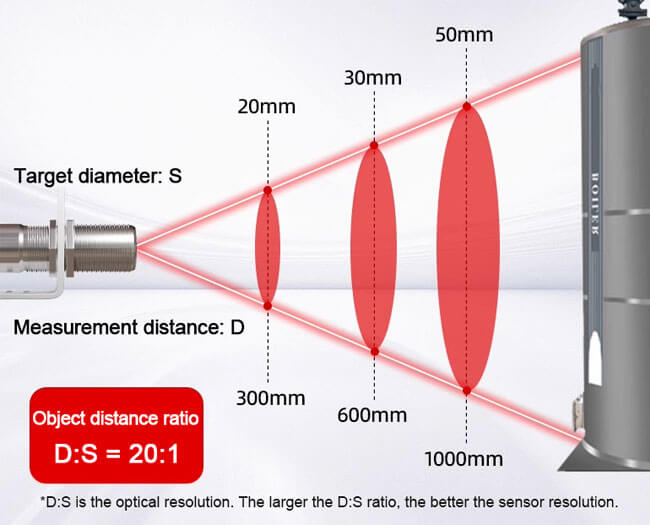

The optical resolution (D:S) of our product is 20:1, it refers to the ratio of the measuring distance to the diameter of the measured object. When the distance between the infrared temperature sensor and the object to be measured increases, the surface area of the object to be measured is required to be larger.

Datasheets

| Output | RS485 type | 4~20mA type |

|---|---|---|

| Power supply | 10V-30V DC | 10V-24V DC |

| Max. power consumption | 0.12W | 1.2W |

| Measure range | 0-100°C, 0-150°C, 0-200°C, 0-300°C, 0-400°C, 0-500°C, 0-600°C, 0-700°C, 0- 800°C, 0-900°C, 0-1000°C, 0-1200°C, -30°C-300°C, -30°C-600°C | |

| Accuracy | ±1% or ±1°C, (@300°C) | ±1% or ±1.5℃ |

| Spectral range | 8~14um | 8~14um |

| Optical resolution (D:S) | 20:1 | 20:1 |

| Emissivity | 0.95 (factory preset) | 0.95 (fixed) |

| Working environment | -20 ~60°C, 10–95% (non-condensing) | 0~60°C, 10–95% (non-condensing) |

| Response time | 300 ms (95%) | 150 ms (95%) |

| Protect class | IP54 | — |

| Shell | 304 stainless steel | 304 stainless steel |

| Cable length | 2m (default) | 1.4m (default) |

| Single Point Laser Sight | Ring Two-Dot Laser Sight | Digital Display | Cooling Jacket |

|---|---|---|---|

|  |  |  |

| $16 | $30 | $35 | $38 |

Why choose us?

Best price

- 0-100℃, 0-200℃, 0-300℃, 0-400℃, 0-500℃, 0-600℃ each price is $52.4

- 0-700℃, 0-800℃ each price is $104.8

- 0-900℃, 0-1000℃ each price is $121.6

- 0-1200℃ each price is $167.7

Our advantages

Contact-based temperature sensors do not work well on moving objects. Infrared temperature sensors are ideally suited for measuring the temperatures of tires, brakes, and similar devices.

No contact means no friction. Infrared sensors experience no wear and tear and consequently have longer operating lives.

Renke is 15 years of the brand manufacturer for monitoring devices, we have advanced technology, and offer professional after-sales. Provide customized services.

A non contact ir temperature sensor can provide greater detail during a measurement than contact devices, simply by pointing it at different spots on the object being read.

The IR temperature sensor can directly display the value with a digital display, that is, the infrared temperature sensor with display.

We have a huge production scale, with a daily output of up to 50,000 pieces, in stock, and guaranteed delivery within 24 hours after payment.

IR Temperature Sensor FAQs

1. How does infrared temperature sensor work?

Working principle

Any object radiates infrared energy and the radiation intensity changes with temperature. Infrared temp sensors use infrared radiation energy with a wavelength in the range of 8μm-14μm. The IR temperature sensor is a kind of optoelectronic sensor, which receives infrared radiation and converts it into an electrical signal, and displays or outputs temperature through electronic circuit amplifier, linearization, and signal processing.

Measuring distance

The size of the measured target and the optical characteristics of the IR sensor determines the maximum distance between the measured target and the measuring head. In order to avoid measurement errors, the measured target should be as full as possible in the field of view of the probe. Therefore, the measured point should always be kept smaller than the measured object or at least the same size as the measured target.

2. What is the temperature range of infrared sensors?

Ranges vary, our IR temperature sensor range have: 0-100℃, 0-150℃, 0-200℃, 0-300℃, 0-400℃, 0-500℃, 0-600℃, 0-700℃, 0-800℃, 0-900℃, 0-1000℃, 0-1200℃.

3. How to clean the lens?

The lens of the infrared temperature sensor must be kept clean to prevent measurement errors or damage caused by contaminants such as dust or smoke. If dust is found on the lens, it should be gently wiped using lens cleaning paper moistened with anhydrous alcohol.

4. How to avoid electromagnetic interference?

To prevent interference from surrounding electromagnetic sources, the infrared temperature sensor should be installed as far away as possible from strong electromagnetic field sources such as motors, engines, and high-power cables. If necessary, a metal shielding sleeve can be used to enhance protection.

5. How to install the infrared temperature sensor?

The front end of the infrared temperature sensor is equipped with an M18×1 threaded interface, allowing for direct installation or installation using a mounting bracket. An adjustable mounting bracket offers greater flexibility in positioning the sensor and adjusting the viewing angle. When aligning the target with the sensor lens, ensure that the optical path is free from obstructions.

6. How to wire the infrared temperature sensor?

RS485 type: RS485 output devices have four wires: brown, black, yellow, and blue. Among them, the brown wire is connected to the positive power supply (10~30V DC), the black wire is connected to the power ground (GND), the yellow wire is connected to 485A, and the blue wire is connected to 485B.

4~20mA type: 4~20mA has two wire colors (the two wire colors are random when shipped). Wire color one: brown wire is connected to +24V, blue wire is connected to signal output 4-20mA+. Wire color two: red wire is connected to +24V, blue wire is connected to signal output 4-20mA+, and there is a gray shielded wire.

7. What is included in the shipping package?

Infrared temperature sensor (4-20mA device with 1.4m cable, RS485 device with 2m cable)*1

Fixing nut, user manual, etc.

8. Can infrared temperature sensors measure through glass?

Most cannot; glass blocks or reflects infrared radiation. Special sensors are required for such applications.

9. What are the applications of infrared temperature sensors?

They are used in industrial process monitoring, HVAC, medical devices, food safety, and electronics.

10. Are infrared temperature sensors safe?

Yes, they are passive sensors and do not emit any radiation themselves.

11. What affects the accuracy of an IR temperature sensor?

Distance, angle, emissivity, environmental temperature, and interference from other heat sources.

Related Blogs

The commonly used communication method for data acquisition and control is RS485. RS485 is a general communication standard. It can not only link devices to

What is a temperature probe? A temperature probe is a sensor that senses temperature and converts it into a usable output signal. Temperature probes are

Table of Contents Smart buildings are the product of the development of modern science. The smart building system is mainly composed of Internet of Things

The key to the smart industry lies in the collection of data and information. Sensors are the nerve endings of the smart industry. They are

Table of Contents What is IoT? IoT is the “Internet of things“. It is an extended and expanded network based on the Internet. It combines

What is temperature and humidity sensor? Temperature and humidity sensors refer to equipment that can convert temperature and humidity into electrical signals which can be

How to wire 485 and analog sensors? RS485 remote temp and humidity sensor has two-wire and four-wire connections. The four-wire system can only achieve point-to-point

Table of Contents What are industrial sensors and actuators? Industrial sensors are devices that can convert physical or chemical quantities in the environment into electrical

Table of Contents What is infrared temperature? This is a non-contact temperature measurement method that measures the surface temperature of a target object by infrared