Table of Contents Water quality parameters are indicators used to assess the condition and trends of aquatic environments. Monitoring is essential for various water sources

Water Conductivity Sensor

RS-EC-*-2-EX water conductivity sensor is a device for measuring the conductivity of a solution. It has an automatic temperature compensation function that can compensate the conductivity of the current temperature to the specified temperature. According to the different applications, we provide two choices of stainless steel electrode and plastic electrode. There are rs485 and analog output options.

- Model: RS-EC-*-2-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: $94.3

About - Water Conductivity Sensor

Water conductivity sensor, also called: water conductivity meter, water conductivity tester, water ec sensor.

Our water conductivity sensor is composed of a data collector and an electrode. When using it, insert the conductivity electrode into the measuring liquid, and the data collector will send the data uploaded to our free platform or customer’s own platform through the RS485 signal or analog signal. Users can remotely view data in real time through a computer or mobile phone.

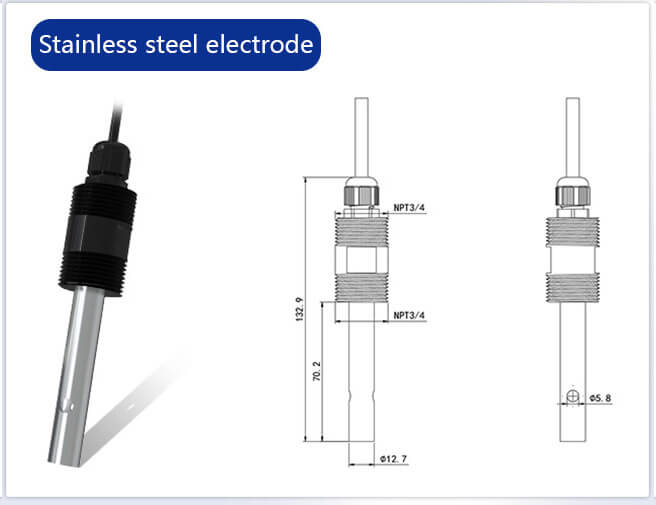

water conductivity sensor with stainless steel electrode

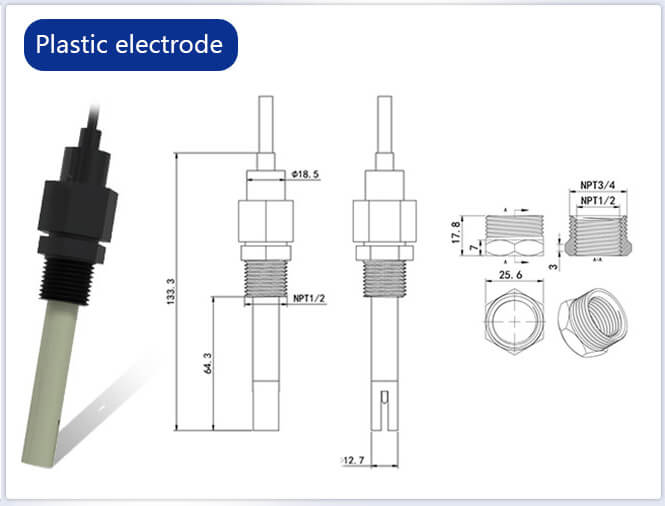

water conductivity sensor with plastic electrode

| Types | Electrode constant | Measure range | Resolution | Applications |

|---|---|---|---|---|

| Stainless steel electrode | K=1 | 1~2000μS/cm | 0.1μS/cm | corrosive liquid |

| Stainless steel electrode | K=10 | 10~20000μS/cm | 1μS/cm | corrosive liquid |

| Plastic electrode | K=1 | 1~2000μS/cm | 0.1μS/cm | non-corrosive liquid |

| Plastic electrode | K=10 | 10~20000μS/cm | 1μS/cm | non-corrosive liquid |

Description - Water Conductivity Sensor

Parameters

| Parameters | RS485 | 4-20mA/0-5V/0-10V |

|---|---|---|

| Power supply | DC 10~30V | |

| Power consumption | 0.4W | 1W |

| Measure range | K=0.01: 0.01~20μS/cm, K=0.1: 0.1~200μS/cm, K=1: 1~2000μS/cm, K=10: 10~20000μS/cm | |

| Accuracy | ±1%FS | |

| Resolution | 0.001μS/cm (0.01~20μS/cm), 0.01μS/cm (0.1~200μS/cm), 0.1μS/cm (1~2000μS/cm), 1μS/cm (10~20000μS/cm) | |

| Temperature compensation range | -20~100℃ (default compensation temperature 25℃) | |

| Temperature compensation coefficient | default 0.02 | |

| Component temperature resistance | -20℃~+80℃, 0%RH~95%RH (non-condensing) | |

| Electrode line length | default 5m (customizable 10m, 15m, 20m) | |

Working principle

The water conductivity sensor working principle: when the conductivity electrode is in the solution, the electrode is equivalent to resistance, and the size of the resistance is inversely related to the conductivity of the solution. When the conductivity of the solution is fixed, the resistance of the electrode is proportional to the electrode constant K. Inverse relationship. Therefore, the measured value of the conductivity of the solution is calculated based on the resistance of the electrode and the constant K of the electrode itself and is obtained through temperature compensation.

Application

EC electrodes can be used with a waterproof data processor or with a digital display controller. Widely use in:

- River/ stream water quality

- Irrigation runoff water quality

- Salinity studies/Estuary monitoring

- Wastewater quality monitoring

- Aquaculture

- Two kinds of probes are available for a wider range of applications.

- Multiple output modes are available: RS485, 0-5V, 0-10V, 4-20ma.

- The sensor adopts a wide voltage power supply, DC 7~30V can be used.

- The shell is IP65 protection grade and can be used in outdoor rain and snow environment.

FAQ- Water Conductivity Sensor

Conductivity refers to the ability to conduct current in a body of water. In water quality monitoring, conductivity is one of the important indicators reflecting the quality of water quality. When the conductivity value of the water is higher, the conductivity is better, and the TDS value in the water is larger. The TDS value represents the content of dissolved impurities in the water. The larger the TDS value, the higher the impurity content in the water. On the contrary, the smaller the impurity content, the higher the water Pure, the lower the conductivity.

The conductivity of water can be measured with a conductivity detector. Put the conductivity probe into the water. Calculate the conductivity value by measuring the change in solution resistance.

Water conductivity sensors are used in water-quality applications to measure how well a solution conducts an electrical current. This type of measurement assesses the concentration of ions in the solution. The more ions that are in the solution, the higher the conductivity.

In normal use, the electrode will not be scratched or corroded and can be used all the time. If the electrode is damaged, the measurement accuracy will be affected, and the electrode needs to be replaced in time.

The temperature compensation of conductivity is to compensate the conductivity value at the current temperature to the conductivity value at the specified temperature (default 25°C). The temperature coefficient is the percentage value of the change in the conductivity of the solution with the temperature, and the percentage change in the conductivity when the temperature rises by 1℃. The default 0.02 (2%) approximates the temperature coefficient of conductivity of potassium chloride solution. The user can set the temperature coefficient value by himself to make the temperature compensation more accurate. The method is to first set the temperature compensation coefficient of the device to 0, and then measure the conductance in the same solution to be tested at two different temperatures (t1, t2) Rate value (g1, g2), and then use the formula to obtain the change in conductivity per 1°C increase Δg=(g1-g2)/(t1-t2), and then measure the conductivity of the solution under test at 25°C, g0 , The temperature coefficient can be calculated as: α= Δg/g0.

It is recommended to calibrate with a standard solution close to the conductivity value of the solution to be tested. If the conductivity value of the solution to be tested is not clear, select a standard solution close to the middle value of the range.

1. Submerged installation: the lead wire of the electrode passes through the stainless steel tube, and the 3/4 thread on the top of the electrode is connected with the stainless steel 3/4 thread with raw material tape. Make sure that no water enters the top of the electrode and the electrode wire.

2. Sidewall installation: The manufacturer provides a 316L full stainless steel sheath with a bevel, and the electrode can be screwed into the sheath.

3. Pipeline installation: connect to the pipeline through the electrode 3/4 thread.

Our water conductivity sensor has been calibrated before leaving the factory. If you need to calibrate it later, you can find a solution with a known conductivity to calibrate it yourself. In the case of long-term use, it is best to calibrate once every three months.

It is recommended to use plastic conductivity electrodes for non-corrosive water, such as: hydrological observation, water plant treatment, aquaculture, etc.

It is recommended to use stainless steel conductivity electrodes for corrosive water, such as environmental protection pharmaceuticals, food processing, sewage treatment, etc.

Under normal conditions, the electrode has a one-year warranty and the data collector has a two-year warranty.

Please contact us for the manual.

Popular water quality sensors

Related Blogs

Table of Contents What is conductivity in water? Conductivity in water is the ability of water to conduct electricity. It is primarily related to the

What is dissolved oxygen? Dissolved oxygen (DO) refers to molecular oxygen dissolved in water. The unit is mg/L, which means how many milligrams oxygen in

Long-term rainfall and melting snow have raised water levels and flooded city roads, causing flooding. Frequent and extreme flooding is inevitable and endangers community safety.

What is a karst cave? The karst cave is a treasure given to mankind by nature and is called a “disposable non-renewable resource” by experts.

Table of Contents Everyone knows that the choice of water quality sensors is very important. In water measurement, the ph sensor is one of the

Table of Contents Water is the source of life, integral to every aspect of human production and daily living. In many scenarios, ensuring health and

Table of Contents What is IoT? IoT is the “Internet of things“. It is an extended and expanded network based on the Internet. It combines

What is smart farming? Smart farming is the application of Internet of Things technology to traditional agriculture, using sensors and software to control agricultural production

Table of Contents What is a water level sensor? The water level sensor is a device that measures the liquid level in a fixed container