What is a vibration sensor?

Vibration sensor is a device that measure the vibration speed and frequency of mechanical motion and convert them into output signals. The vibration frequency and amplitude of mechanical equipment work can reflect whether the equipment is faulty, such as: screws loose, parts aging, etc..

Vibration sensors can convert changes in vibration into an electrical signal output and provide information about displacement, velocity and acceleration. Once the measurement results are abnormal, it indicates that there is a hidden problem or failure of the machinery, and timely check for bearing wear, misalignment of parts and other problems.

Why do you need to monitor vibrations?

The requirements for motors and other equipment are increasing in industrial production processes. Managers not only need to ensure their normal operation but also their long-term functionality. During the operation of the equipment, issues such as component detachment, equipment aging, and inadequate fastening can result in abnormal vibrations. Various vibration sources exist in any equipment, such as bearing defects, imbalance, and gear meshing, each causing vibrations with different frequencies and directions. The vibration signals of the equipment provide information about its condition, with different signals representing different operational information. Therefore, by analyzing and detecting the vibration signals of the equipment, potential faults can be identified, preventive measures can be taken in a timely manner, and accidents can be avoided or minimized.

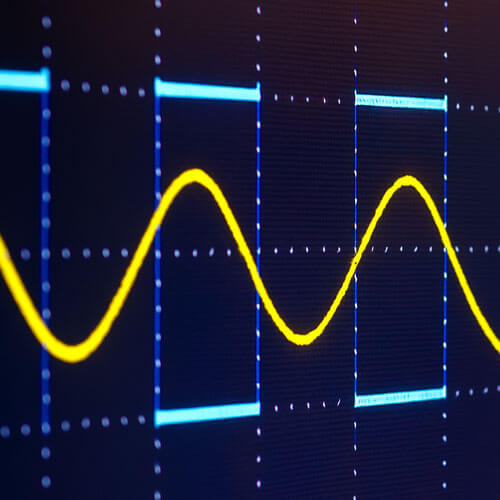

How does a vibration sensor work?

A vibration sensor does not simply convert mechanical quantities into electrical energy. Instead, it uses the original mechanical quantity as an input signal and then converts it into a suitable mechanical quantity through the mechanical receiving component. Finally, it is converted into electrical energy through the electromechanical conversion component. Therefore, the data depends on the working condition of its mechanical receiving component and electromechanical conversion component.

How many different types of vibration sensors are there?

There are multiple types of vibration sensor. Next, I will introduce seven of the most commonly used vibration sensors, along with their advantages, disadvantages, and applications.

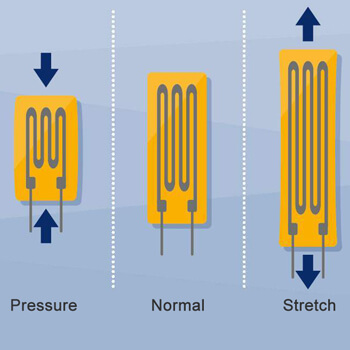

1. Strain Gauges

A strain gauge is a resistance-strain sensor that converts the strain applied to a material into a change in electrical resistance. It consists mainly of a metal foil, which is mounted for use by, for example, sticking it on the test object. When stress is applied to a material, the material undergoes a deformation in tension or compression, which is also known as strain. Strain gauges are used as piezoresistive sensors, where the change in resistance value is directly proportional to the deformation produced. By measuring the value through a bridge circuit, the actual magnitude of the load applied to the material can be known. Because of the thin metal foil in the strain gauge, even small changes in resistance can be measured accurately.

Pros:

No moving parts, hence no wear and tear.

Small in size and low cost.

Very sensitive to changes in resistance, enabling measurement of even small changes.

Cons:

Highly sensitive to temperature.

Requires regular calibration.

Requiring high installation precision.

Application: In the field of mechanical engineering, strain gauges are commonly used for dynamic and static strain testing, such as measuring the fatigue properties of materials, wheel moment testing, and strain analysis of rectangular thin plates. Strain gauges can be used in load testing of concrete and steel structures, e.g. monitoring deformation and strain in buildings and bridges, seismic performance testing, etc. Strain gauges are used in sensors and controllers for troubleshooting and optimizing performance by testing and monitoring structural strains in vehicles.

2. Accelerometers

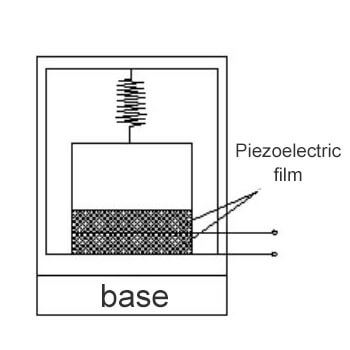

Accelerometers operate based on the principle of converting mechanical vibrations or forces (acceleration) into proportional electrical charges using piezoelectric materials. When a mechanical device is stationary, accelerometers can measure static acceleration (continuous gravitational force from the Earth) and analyze the device’s tilt angle relative to the Earth. During device operation, accelerometers can measure dynamic acceleration (vibration or rotation) and analyze the device’s displacement and vibration frequency. There are single-axis accelerometers and triaxial accelerometers depending on the measurement direction. Single-axis accelerometers measure vibration along a single axis, while triaxial accelerometers can measure vibration along three mutually perpendicular axes. Single-axis and triaxial accelerometers can be configured with specifications such as sensitivity, temperature, frequency response, and amplitude response.

Pros:

Various installation methods.

Wide range of applications.

They can simultaneously monitor equipment temperature.

They can be used for both high-frequency and low-frequency measurements, offering good stability.

Cons:

Accelerometers need to be in contact with the equipment to measure vibrations.

They require secure fixation before use.

Noise can impact the monitoring results.

Application: Vibrations of rotating machinery are monitored using accelerometers. They are used in devices such as tablets and digital cameras to ensure that the images on the screen are always displayed upright. In unmanned aerial vehicles, accelerometers contribute to stabilizing flight.

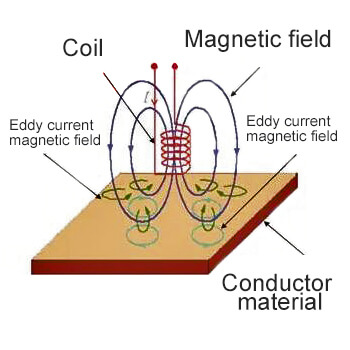

3. Eddy Current or Capacitive Displacement Sensors

Eddy current sensors work by utilizing the phenomenon of electromagnetic induction. When a metal conductor is placed in a changing magnetic field, induced currents are generated inside the conductor. These currents form a closed loop that resembles the shape of a water vortex, hence the name eddy current. The eddy current sensor is mainly composed of several parts such as probe, extension cable and front. It is mainly used to measure the vibration, displacement, eccentricity and other data of rotating machinery during operation. According to the penetration of eddy current in the conductor, the sensor can be divided into two categories: high-frequency reflective and low-frequency transmissive.

Pros:

Non-contact measurement

High sensitivity for detecting surface-defective workpieces.

Can detect through different layers.

Good in harsh environments with pressure, temperature, dirt, and oil.

Cons:

Measurement targets must be conductive metals.

Susceptible to changes in magnetic permeability.

Not suitable for large-area measure.

Eddy current sensors can measure the shaft displacement of rotating machinery and monitor whether the machinery is in optimal working condition. This type of vibration sensor exhibits excellent performance in environments with oil, dirt, dust, moisture, and magnetic field interference. It is one of the best non-contact sensors for measuring displacement and position in harsh industrial environments.

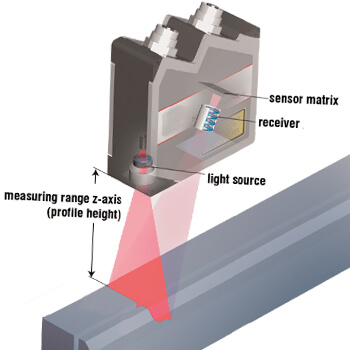

4. Laser Displacement Sensors

A laser displacement sensor is used for precise non-contact measurement of the position, displacement, and other changes of an object. It is mainly applied in measuring geometric quantities such as displacement, thickness, vibration, distance, and diameter of objects. Based on the measurement principles, laser displacement sensors can be categorized into laser triangulation and laser echo analysis methods. Laser triangulation is generally suitable for high-precision and short-distance measurements, while laser echo analysis is used for long-distance measurements.

Pros:

Non-contact measurement, leading to longer lifespan and no wear.

Short response time.

High precision.

Capable of measuring small objects.

Cons:

The laser emitter and receiver windows and lenses of the sensor are susceptible to contamination from dust and oil.

The proper installation angle is required, as being too close or too far can affect measurement results.

Triangulation Method

In the triangulation method, a laser emitter projects visible red laser light onto the surface of the object to be measured. The scattered laser light from the object is received by a lens and detected by an internal CCD linear camera. Based on the different distances, the CCD linear camera “sees” the light spot at different angles. With this angle and a fixed distance (between the laser and the camera), the digital signal processor can calculate the distance between the sensor and the object being measured.

Echo Analysis Method

Inside the sensor is composed of a processor unit callback processing, unit laser transmitter, laser receiver and other parts. The laser displacement sensor emits 1,000,000 laser pulses per second through the laser transmitter to the detected object and back to the receiver unit of the sensor. The processor calculates the time it takes for the laser pulse to encounter the detected object and return to the receiver. From this, a distance value is calculated and this output is averaged over thousands of measurements.

Application: Laser displacement sensors are well-suited for environments that require high speed, high measurement accuracy, and long-distance measurement of numerous targets.

5. Gyroscopes or Angular Rate Sensors

A gyroscope, also known as an angular rate sensor, measures the rate of change of angular velocity around an axis. A flywheel rotor rotating at high speed around an axis of symmetry is called a gyro. A gyro is mounted on a frame device that gives the gyro’s spin axis degrees of freedom for angular rotation, this device is called a gyroscope. Its working principle is based on the principle of Coriolis force: when an object moves in a straight line in a coordinate system, assuming that the coordinate system makes a rotation, then during the rotation, the object feels a perpendicular force and acceleration in a perpendicular direction.

Pros:

Small size and lightweight.

Fast operation, capable of measuring angular velocity.

High resolution and low drift.

Cons:

Requires high calibration accuracy, resulting in longer production time.

Low stability concerning temperature, humidity, and stress.

Application: Gyroscope sensors are primarily used in the automotive industry to determine the yaw angle (rotation of a vehicle around its vertical axis) or roll angle (rotation of a vehicle around its longitudinal horizontal axis) during vehicle motion.

6. Microphones or Acoustic Pressure Sensors

The working principle of acoustic pressure sensors, or microphones, is to detect mechanical waves or sound waves. When sound waves propagate through a material or on the surface of a material, any changes in the propagation path can affect the velocity and/or amplitude of the waves. Acoustics is a major field in vibration testing.

Pros:

Cost-effective method for high-frequency vibration measurement.

Low cost and easy to operate.

Can accurately represent the frequency content in vibrations.

Cons:

Susceptible to environmental interference.

Limited application range.

Measures relative changes.

Application: Acoustic pressure sensors are used for vibration measurements. It can be used to assess liquid flow and vibration and also to measure different liquid pressures. It can both detect imbalances between liquids and solids (e.g. temperature changes) and measure molecular motion in liquids. Used as a liquid pressure sensor or in vibration compensation systems to measure the vibration of a machine, and in fluid mechanics to measure the pressure exerted by a fluid on its vibration.

7. Handheld Vibration Analyzer

A vibration analyzer is an instrument used to monitor the frequency of mechanical vibrations. It is typically handheld and used for vibration assessment, diagnostics, and quality control in equipment operations. A handheld vibration sensors provides real-time measurement data, allowing users to directly read vibration values by connecting the sensing end to the machine. Based on the data provided by the vibration analyzer, decisions can be made regarding maintenance or repairs. It enables quick testing of the vibration frequency of a machine.

Pros:

Portability and ease of use.

Fast and accurate measurement values.

Offers measurement, storage, diagnostics, and analysis functions.

Wireless operation, no need for installation.

Cons:

Expensive price.

Cannot provide continuous measurements.

Application: Handheld vibration analyzers can be used in various settings such as manufacturing plants, product development laboratories, construction sites, and other places. They are indispensable for advanced vibration measurement and analysis experts.

How to mount a vibration sensor?

Magnetic Mounting

In industrial applications, magnetic bases are commonly used when sensors require periodic point-to-point fast measurements. When using a magnetic base for installation, the magnetic force causes the adapter and sensor to move towards the mounting surface. However, upon contact, the magnetic force can create significant impact on the accelerometer, potentially damaging the sensor chip or its internal electronic components. Magnetic mounts are most suitable for low-frequency testing where the vibration frequencies are relatively small. When magnetic mounting is used for mid-frequency testing, it is necessary to treat the test surface effectively to increase its resonance frequency.

Bolt Mounting

The preferred method for vibration sensor installation is using bolts. By directly fixing the vibration sensor to the bearing with bolts, not only can vibrations in three directions at the top of the bearing housing be measured, but vibrations in two directions on the vertical plane can also be measured. This mounting method provides the most secure attachment.

Adhesive Mounting

In many cases, it is required to install the vibration sensor without damaging the mounting surface, for example, when threaded holes cannot be installed on the mounting surface (due to composite surface materials, insufficient structural thickness, small mounting surface, or multiple mounting points). Adhesive mounting is used in such situations. The hardness of the cured adhesive plays a crucial role in the testing of the entire system. The more adhesive between the sensor and the surface of the structure being tested the poorer the transmission performance. When using adhesive for sensor installation, the operating temperature is an important factor to consider. Adhesives include hot-melt adhesives, super glues, waxes, and double-sided adhesive tapes.

Where is the vibration sensor application?

Mechanical Industry

The vibration sensor can be used for troubleshooting mechanical transmission systems. Transmission system failures are often caused by damage to bearings, gears, couplings and other components, and vibration sensors can detect the specific cause of the failure, thus helping the transmission system to carry out rapid fault diagnosis and repair. In industrial production, mechanical equipment will produce a certain amount of vibration, and vibration sensors can detect the parameters of these vibrations, such as frequency, amplitude, phase, etc., so as to achieve an accurate analysis of the vibration of mechanical equipment.

Aerospace Industry

The vibration sensor can be used to monitor the vibration of aircraft, rockets, and other flying vehicles. They can measure the vibration of the aircraft during flight, takeoff, and landing. This provides data support for normal flight operations, helps optimize designs, and extends the lifespan of the aircraft.

Automotive Industry

The vibration sensor can be used for automotive fatigue and failure monitoring. Vibration sensors monitor the vibration of components such as wheels, brakes and engines during vehicle operation. They can predict component damage and failure so that they can be repaired or replaced in a timely manner, improving vehicle safety and reliability.

Energy Industry

The vibration sensor is used to detect and monitor vibrations in generators and transformers for fault prediction. For example, they are used in wind turbines to monitor turbine bearing vibrations to determine potential failure or wear.

Construction Industry

The vibration sensor can monitor the vibration of buildings. During the construction and operation of structures such as subways and high-rise buildings, vibration sensors can monitor the vibration data of the buildings, allowing for the prediction of deformation and damage.

Seismic Exploration

The vibration sensor can be used to measure vibrations in the ground in order to learn about substances underground. For example, vibration sensors can be used to detect vibrations in the ground when searching for oil, gas or mineral resources. In addition, vibration sensors can be used to monitor earthquakes and other geologic hazards in order to provide early warning information when needed.