Table of Contents What is Modbus? Modbus is a serial communication protocol used for communication with Programmable Logic Controllers (PLCs).

Industrial Vibration Sensor

There are high-performance MEMS chips in the vibration sensor, using embedded, temperature sensor, and vibration sensor technology. By measuring the vibration of mechanical equipment, it can reflect whether the machinery is in the best working condition. Widely used in rotating equipment such as reducer fans, generators, air compressors, centrifuges, and water pumps.

- Model: RS-WZ3/WZ1-*-1-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: $46.1~$230.6

Industrial vibration sensor view

When the object makes regular reciprocating motion in the equilibrium position, it is called mechanical vibration. There will be mechanical vibration when industrial equipment is running. When the mechanical equipment is working, the vibration signal can judge the status of the equipment, and different signals represent different equipment information. The industrial vibration sensor is used to measure fluctuating acceleration or velocity or for normal vibration measurements. Workers use vibration sensors to predict machine maintenance to reduce overall costs and improve machine performance.

When equipment components or the environment change. Its welding points and connectors are easy to loosen and even cause permanent damage. If it is not discovered in time and the mechanical equipment continues to operate under such conditions, the equipment will vibrate abnormally and fail. Our industrial vibration sensors can continuously measure equipment vibration, helping technicians to do preventive maintenance work in time and avoid major failures. The vibration and temperature sensor has many output signals, the more commonly used ones are analog output, rs485 output, and LoRa output.

The temperature vibration sensor uses 485 signal or LoRa signal to measure the speed of X, Y, and Z axes. Measure the vibration velocity, vibration displacement and temperature. If the vibration acceleration is to be measured in the use environment, it is also possible. For our temperature vibration sensor, the vibration speed range is generally 0-50mm/s. If the measuring equipment does not match this range, you can choose any other range.

| Lora temperature vibration sensor price | ||||

|---|---|---|---|---|

| Unit($) | Single axis(10-1600Hz) | Three axis(10-1600Hz) | Single axis(10-5000Hz) | Three axis(10-5000Hz) |

| M8 thread | 146.8 | 157.3 | 209.7 | 230.6 |

| M5 thread | 146.8 | 157.3 | 209.6 | 230.6 |

| Magnetic | 151 | 161.5 | 213.9 | 234.8 |

| RS485 temperature vibration sensor price | ||||

|---|---|---|---|---|

| Unit($) | Single axis (10-1600Hz) | Three-axis (10-1600Hz) | Single axis (10-5000Hz) | Three-axis (10-5000Hz) |

| Normal type | 46.1 | 65 | 134.2 | 142.6 |

| Spectrum type | —— | 69.2 | —— | 146.8 |

| Magnetic | 50.3 | 69.2 | 138.4 | 146.8 |

| Analog temperature vibration sensor price | ||||

|---|---|---|---|---|

| Unit($) | 4-20mA | 4-20mA (two wires) | 0-5V | 0-10V |

| Single axis (10-1600Hz) | 46.1 | 52.4 | 46.1 | 46.1 |

| Single axis (10-5000Hz) | 134.2 | 144.7 | 134.2 | 134.2 |

Types of vibration sensors

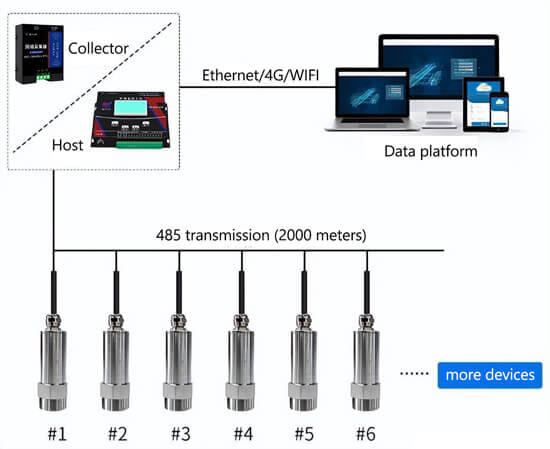

The transmission distance is long, up to 2000 meters, which can realize remote monitoring. If there are few measuring points, you can choose a network collector, which can not only reduce the cost, but also meet your own needs.

Modbus vibration sensor

The RS485 vibration sensor uses a 10-30V DC wide voltage power supply. Suitable for dry, humid, noisy, and other environments, waterproof and dustproof. The measurement data is transmitted through the signal line, free from environmental interference, safe and stable. The Modbus vibration sensor can measure a single axis or three axes.

- Power supply: DC10-30V

- Frequency range: 10-1600Hz

- Working environment: -40℃~+80℃, 0%RH~80%RH

- Vibration speed range: 0-50mm/s

- Vibration velocity accuracy: ±1.5% FS (@1kHz, 10mm/s)

- Vibration velocity resolution: 0.1mm/s

- Vibration displacement range: 0-5000μm

- Vibration displacement resolution: 0.1μm

- Surface temperature range: -40~+80℃

- Temperature display resolution: 0.1°C

Lora vibration sensor

In an environment without wiring and power supply, the factory can choose LoRa wireless transmission. The industrial vibration sensor does not require wiring, the signal transmission distance is long, and the penetrating ability is strong. The sensor has a built-in high-capacity lithium sub-battery, which can work normally for 3-5 years. The wireless vibration sensor transmits the data to the LoRa gateway, and the LoRa gateway uploads the data to the monitoring platform with Ethernet or 485 signal.

The wireless vibration sensor is easy to use, and the wireless digital signal transmission method eliminates the noise interference caused by long cable transmission. The entire measurement system has extremely high measurement accuracy and anti-interference ability. Wireless vibration sensor nodes can form a huge wireless sensor network to monitor multiple locations simultaneously. The node structure is compact and the data transmission is fast. The wireless vibration sensor is compact and easy to install.

The wireless vibration sensor transmits the LoRa signal to measure the motor surface temperature, vibration speed and other data in real-time. Users can view it on their mobile phones or computers anytime, anywhere, fully grasp the operation of the motor, and establish a complete monitoring system for rotating equipment. It is a triaxial vibration sensor that can measure the vibration speed of X/Y/Z three axes.

- Power supply: 3.6V lithium battery

- Frequency range (Hz): 10-1600/10-5000 (optional)

- Working environment: -40℃~+80℃, 0%RH~80%RH

- Vibration speed range: 0-50mm/s

- Vibration velocity accuracy: ±1.5% FS (@1kHz, 10mm/s)

- Vibration velocity resolution: 0.1mm/s

- Surface temperature range: -40~+80℃

- Temperature resolution: 0.1°C

- Configuration method: Bluetooth configuration

Analog vibration sensor

Analog vibration sensor, which can convert vibration signal into analog output. The measuring point data is collected and uploaded to the host computer through the PLC. The staff can monitor the vibration velocity, displacement and temperature changes of each measuring point in real time. Analog vibration sensors can only measure a single axis. The output modes are 0-5V, 0-10V, 4-20mA.

- Power supply: DC10-30V

- Frequency range (Hz): 10-1600 or 10-5000 (optional)

- Vibration measurement direction: uniaxial, perpendicular to the direction of the measurement surface

- Working environment: -40℃~+60℃, 0%RH~80%RH

- Vibration speed range: 0-50mm/s

- Surface temperature range: -40~+80℃

- Vibration velocity accuracy: ±1.5% FS (@1kHz, 10mm/s)

Our vibration sensor features

- The protection grade is IP67. The shell is 304 stainless steel, small and durable. This iot vibration sensor can be used in many environments.

- Can measure X, Y, Z three-axis speed. The vibration speed range is 0-5000μm, whether it is 0-100μm, 0-200μm, 0-1000μm equipment, or 0-2000μm equipment, all ok.

- Installing industrial vibration sensor at different measuring points, the vibration signals and temperature changes of the equipment can be measured. Then upload it to the data platform, and users can grasp the equipment status anytime and anywhere.

- Users can filter by time in the historical data in the platform at any time, and quickly query the required data. It is also possible to convert the data into monthly reports and weekly reports, and export and print them in forms/polylines.

- When the device information is abnormal, the system will send the alarm information to the contact person by phone, text message, page turning red, email, etc.

- The user can check the alarm information and frequency through the historical record, so as to judge the mechanical operating life. Determine whether major repairs or replacements are required.

How to mount vibration sensor

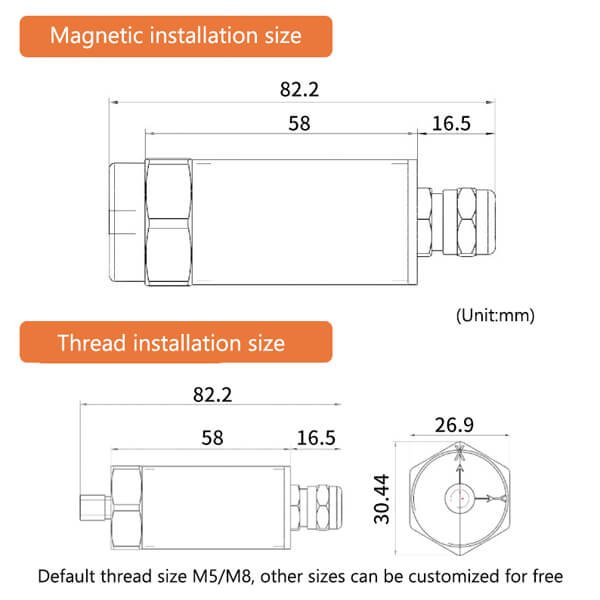

If the use environment permits, you can choose threaded installation. Standard threads on the metal housing provide quick connection to the mounting site. Our industrial vibration sensor thread has two specifications of m8*1.25*10 and m5*7 external thread. If the installation part has no thread and cannot be drilled, then you can choose magnetic installation, just need to adsorb the industrial vibration sensor on the installation part.

No matter which installation method you choose, you can timely and accurately measure vibration changes caused by loose parts, damaged rolling bearings, damaged gears, etc. Send an alarm to the user for the detected fault to prevent the machine from continuing to work in a bad state and causing damage.

FAQ

How does a vibration sensor work?

The industrial vibration sensor mainly receives the mechanical quantity and converts it into a proportional electric quantity. Therefore, the working performance of the sensor is determined by the mechanical receiving part and the electromechanical conversion part.

How to calibrate vibration sensor?

Our industrial vibration sensor has been calibrated before leaving the factory and does not require secondary calibration. If calibration is required after long-term use, please contact our professional technicians.

Where are vibration sensors used?

The industrial vibration sensor can collect data from three axes of machinery at the same time. It is suitable for online measurement of temperature and vibration of rotating equipment such as motors, generators, reducers, fans, air compressors, centrifuges, and submersible pumps.

How many types of vibration sensors are there?

According to the electromechanical conversion principle: electric, piezoelectric, eddy current, inductive, capacitive, piezoresistive.

Related blogs

Table of Contents What is a vibration sensor? Vibration sensor is a device that measure the vibration speed and frequency

Table of Contents With the development of technology, the Internet of Things (IoT) has become an indispensable part. It connects

Long-term rainfall and melting snow have raised water levels and flooded city roads, causing flooding. Frequent and extreme flooding is

Table of Contents Biologists think the human nose can distinguish about 10,000 odors. A dog’s nose can distinguish about 2

The commonly used communication method for data acquisition and control is RS485. RS485 is a general communication standard. It can

With the development of Internet of Things technology, sensors and wireless transmission technology are widely used in smart agriculture. Smart

Measuring tilt angles is an important part of geometric metrology. The range of angle measurement is wide. According to the

Table of Contents Smart buildings are the product of the development of modern science. The smart building system is mainly

The key to the smart industry lies in the collection of data and information. Sensors are the nerve endings of

Table of Contents Water is the source of life, integral to every aspect of human production and daily living. In