Table of Contents What is the wind speed and direction? Wind is a physical quantity that represents the movement of

Aluminum Wind Speed Sensor

This aluminum wind speed sensor shell is made of high-quality aluminum alloy profiles, and the exterior is sprayed with plastic. It has good anti-corrosion and anti-corrosion characteristics, which can ensure the long-term use of the transmitter without corrosion. We offer rs485 wind speed sensor, 4-20mA wind speed sensor, 0-5V wind speed sensor, 0-10V wind speed sensor, pulse wind speed sensor.

- Model: RS-FSA-*-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: USD 29.5

About - Aluminum wind speed sensor

Our aluminum wind speed sensor has RS485, 0-5v, 0-10v, 4-20ma, pulse, and other output methods. Please leave us a message for the output method you need, and we will provide you with a specific manual.

Aluminum wind sensor description

Renke aluminum wind speed sensor is small and light, easy to carry and assemble. The three-cup design can effectively obtain wind speed information. The shell is made of high-quality aluminum alloy profiles, and the surface is treated with a plastic spraying process, which has good anti-corrosion and waterproof effects. Even if the wind speed sensor is used in the field for a long time, it will not rust. Bearings are carefully designed and distributed, with low rotational inertia and sensitive response. The base is designed with stable mechanics, with strong bearing force, is easy to assemble and carry, and can work normally in harsh environments.

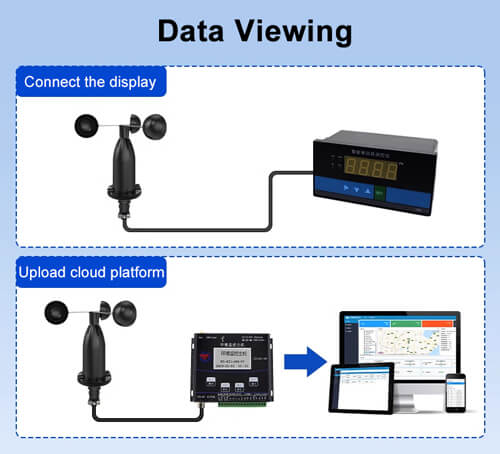

Aluminum wind speed sensor is widely used in wind speed measurement in greenhouses, environmental protection, weather stations, ships, docks, and breeding. To facilitate you to view data at any time, we provide a free cloud platform for viewing data on a computer or mobile phone.

Wind speed meter datasheets

Material: aluminum alloy

For: Wind speed sensor / weather station

Measuring range: 0~60m/s

Accuracy: ±(0.2+0.03V) m/s V means wind speed

Resolution:0.1m/s

Dynamic response time: ≤2s

Power supply: 5~30VDC

Output form: current 4~20ma, voltage 0~5V, 0~10V, RS485, pulse

Instrument line length: standard: 2.5 meters

Load capacity: current type resistance≤600Ω Voltage type resistance≤250Ω

Working environment: -40 ℃ ~ 60℃, 0%RH~80%RH

Protection level: IP65

Power consumption: <1W

Aluminum wind speed meter features

Appearance structure design is reasonable, beautiful and generous, small in size, easy to install.

High measuring accuracy, wide measuring range, and good stability.

Wide range of power supply, good linearity of data information, and long signal transmission distance.

Good dynamic characteristics, strong resistance to external interference, and high measurement accuracy.

Low power consumption, long circuit life, and long-term stable operation.

It has high corrosion resistance and weather resistance.

Aluminum wind speed sensor faq

It was first described in 1846 by the Irish astronomer T. R. Robinson. The first cup anemometers had 4 cups. Patterson (1926) found that if the rotor had only 3 cups the torque is more uniform through the entire revolution.

It has the same function as an anemometer. In fact, most wind speed sensors are used to measure wind speed. The principle is based on the degree of wind’s influence on various natural things. For example, three-cup wind speed sensors and fan wind speed sensors are based on wind speed. The size of the wind speed data is fixed, while the hot-air sensor measures the resistance temperature based on the influence of the wind.

When the wind blows from the left, the wind cup 1 is parallel to the wind direction, and the force component of the wind pressure on the wind cup 1 in the direction most straight to the axis of the wind cup is approximately zero. Wind cups 2 and 3 intersect with the wind direction at an angle of 60 degrees. For wind cup 2, its concave surface faces the wind and bears the greatest wind pressure. The wind cup 3 has a convex surface facing the wind, and the effect of the wind makes the wind pressure received by the wind cup 2 smaller than that of the wind cup 2. The wind cup starts to go smoothly due to the pressure difference between the wind cup 2 and the wind cup 3 in the direction perpendicular to the axis of the wind cup. Rotating in the clockwise direction, the greater the wind speed, the greater the initial pressure difference, the greater the acceleration generated, and the faster the wind cup rotates.

After the wind cup starts to rotate, because the cup 2 rotates in the direction of the wind, the pressure of the wind is relatively reduced, while the cup 3 rotates at the same speed against the wind, the wind pressure is relatively increased, and the wind pressure difference is continuously reduced. After a period of time (when the wind speed is constant), when the partial pressure difference acting on the three wind cups is zero, the wind cups will rotate at a uniform speed. In this way, the wind speed can be determined according to the speed of the wind cup (the number of turns per second).

When the wind cup rotates, it drives the coaxial multi-tooth cutting disc or magnetic rod to rotate, and the pulse signal proportional to the speed of the wind cup is obtained through the circuit. The pulse signal is counted by a counter, and the actual wind speed value can be obtained after conversion. At present, the new type rotor anemometer adopts three cups, and the performance of the cone cup is better than that of the hemispherical cup. When the wind speed increases, the rotor cup can quickly increase the speed to adapt to the airflow speed. When the wind speed decreases, due to the influence of inertia, the speed However, it cannot drop immediately. The wind speed indicated by the rotary anemometer in gusty wind is generally too high (the average error produced is about 10%).

Under normal environment, our wind speed sensor has a service life of 5-8 years, and the overall warranty is 2 years.

To put it simply, it is the minimum wind speed that your wind speed sensor can test from no wind state to wind state.

First, consider the use environment and choose the appropriate wind speed sensor according to the environmental requirements. If used with a weather station, you can choose a polycarbonate wind speed sensor. For long-term outdoor use, you can choose an aluminum shell wind speed sensor. If you want to measure the wind speed in the tube, choose the duct-type wind speed sensor, if you want high-precision data, you can use an ultrasonic wind speed and direction sensor.

You can use a multimeter to detect the quality of the wind speed sensor. However, a multimeter cannot be used to detect the magnitude of the wind speed.

Connect the anemometer to the device, slowly turn the wind blade by hand, measure the voltage between the two wires of the anemometer with the multimeter voltage file, and you can see that the multimeter voltage reading is between high (such as 5v) and low (such as 0v) under normal conditions. change. This is the result of low-speed pulse measurement.

An anemometer is an instrument that measures air velocity. There are many types of it. The most commonly used wind cup anemometer in meteorological stations is the sensing part of three parabolic cones and empty cups fixed on a support at 120° each other. The concave surfaces of the empty cups all face one direction. The whole sensing part is installed on a vertical rotating shaft. Under the action of wind, the wind cup rotates around the shaft at a speed proportional to the wind speed.

No

The wind speed sensor generally measures the wind pressure and calculates the wind speed based on the wind area of the sensor

The air volume sensor generally measures the wind pressure, and calculates the flow rate per unit area while calculating the wind speed.

Related blogs

The weather sensors are the sensing end of the weather station and collect various weather-related data. The weather station can

A greenhouse is a closed environment that provides optimal conditions for plant growth and promotes plant growth by controlling indoor

Table of Contents What is an anemometer? An anemometer is an instrument that measures the velocity of air, sometimes called

Table of Contents How wind sensor work? Wind speed sensor working principle Wind speed sensor is a physical device used

Table of Contents Where to mount wind sensor? Installing wind sensor on the weather station The wind sensor is a

A complete set of a weather station is composed of two parts: hardware and software. The hardware part includes various

Table of Contents Do you know where to mount weather station? The weather station should be installed as far as

Difference between wind speed sensor and air volume sensor The difference between the wind speed sensor and the air volume