Biologists think the human nose can distinguish about 10,000 odors. A dog’s nose can distinguish about 2 million different odors, and it also has a high “analytical ability”. A specific smell can be found from many mixed smells. Even so, there are still many colorless and odorless gases in nature that neither humans nor animals can smell. Therefore, we use gas sensors to measure the concentration of different gases.

A gas sensor detects a specific gas and measures whether the gas is present near the sensor, or its content in the air. Therefore, gas sensors are often indispensable in safety systems. The gas sensor has many different types and can measure different gases. There are sensors that measure non-toxic gases such as oxygen and carbon dioxide, and sensors that detect toxic gases such as carbon monoxide, TVOC, and ammonia. Gas sensors are often used in flammable, explosive and toxic places to protect workers.

What is a gas sensor?

Gas sensors use physical or chemical reactions to convert the concentration of various gases into electrical signals, and output values after calculation. Widely used to detect toxic and harmful gases and natural gas leaks.

The gas sensor is a device used to monitor the presence or level of gas in a stationary environment. Commonly used in coal mines, petroleum, chemical, municipal, medical, transportation, family, and so on. Gas sensors can measure the presence and concentration of combustible, flammable, toxic gases, or oxygen consumption.

Gas sensors types

There are many gas sensors types, in order to choose the most suitable gas sensor, we need to understand the various sensor characteristics. For example: Which sensor can measure toxic gases? Which sensor is convenient to carry? Which sensor measures more accurately? If you know enough about the sensor, you can definitely make the right choice.

According to different gas types: it can be divided into combustible gas sensors (often using catalytic combustion, infrared, thermal conductivity, semiconductor type), toxic gas sensors (generally using electrochemical, metal-semiconductor, photoionization, flame ionization), Harmful gas sensors (often infrared, ultraviolet, etc.), oxygen (often paramagnetic, zirconia) and other types.

According to different usage methods: it can be divided into portable gas detectors and fixed gas detectors.

According to different sampling methods: it can be divided into diffusion sensors (the sensor is directly installed in the measured environment, and the measurement gas is in direct contact with the detection unit through natural diffusion), pumping sensors (through the suction pump, etc., the gas is sucked into the detection unit. According to whether the gas needs to be diluted, it is divided into complete inhalation and diluted inhalation).

According to different functions: it can be divided into a single gas sensor (only one gas can be detected) and a composite gas sensor (can detect multiple gases at the same time).

According to the different detection principles: it can be divided into semiconductor gas sensor, electrochemical gas sensor, NDIR gas sensor, catalytic gas sensor, thermal conductivity gas sensor, magnetic gas sensor and so on.

Classification according to different working principles is currently the most commonly used. The following article will introduce you to seven gas sensors in detail, as well as their principles and applications:

1. Semiconductor Gas Sensors

A semiconductor gas sensor is a device that uses a semiconductor element as a measuring unit. Its working principle is that the gas undergoes a redox reaction on the semiconductor, which causes the resistance value to change. As the gas passes through the measuring cell, it adsorbs on its surface and reacts. Gas levels are measured by causing a change in conductivity or potential characterized by carrier motion.

For example, when methane gas passes through the measuring cell, a reaction occurs that consumes oxygen. The pinned electrons are released, and the electrons are returned to the semiconductor, increasing the conductivity. When the electrons are fixed by oxygen, the resistance increases; when the methane reacts with oxygen, and the electrons return to the semiconductor, the resistance decreases. The resistance change is related to the presence, absence and amount of methane, and the methane content can be known by measuring the resistance change.

Advantages: simple structure, low price, high detection sensitivity, fast reaction speed, etc.

Disadvantages: The measurement linear range is small. It is greatly interfered by other gases in the air, and is easily affected by the ambient temperature.

This is the most common gas sensor, widely used to detect combustible gas leak detection in homes and factories, and suitable for methane, liquefied gas, hydrogen, etc.

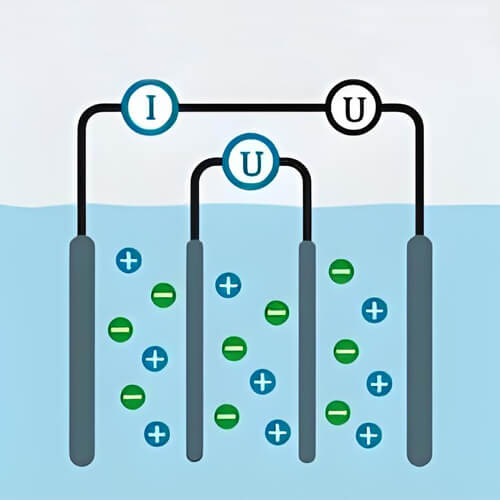

2. Electrochemical Gas Sensors

Electrochemical sensors react with the measured gas and generate an electrical signal proportional to the gas concentration. Most electrochemical gas sensors are current sensors, producing a current that is linearly proportional to the gas concentration.

The electrochemical gas sensors working principle: the gas passes through a diaphragm that prevents condensation, and this diaphragm also has a dust-proof effect. The gas molecules then diffuse through the filter and reach the working electrode. Here, the gas is oxidized or reduced, and this electrochemical reaction causes a change in the current flowing through the external circuit.

Sensors based on electrochemical working principles, the simplest is a two-electrode system. Its working electrode and opposite electrode are separated by electrolyte and connected to the external circuit with a small resistance. When the gas diffuses into the sensor, it reacts to generate an electric current. The more gas the greater the current.

Advantages: fast response, good linear output and other advantages.

Disadvantages: It needs to be detected in an environment with oxygen (1-10% VOL), and liquid electrolytes need to be consumed during use. Easily disturbed by temperature, humidity, pressure, and gases with similar chemical properties. If there is mixed gas on site, it is easy to cause errors.

This gas sensors are widely used in gas detection in industrial and civil fields. It can detect ozone, formaldehyde, carbon monoxide, ammonia, hydrogen sulfide, sulfur dioxide, nitrogen dioxide, oxygen and other gases. It is often used in portable instruments and gas online monitoring instruments.

3. NDIR Gas Sensors

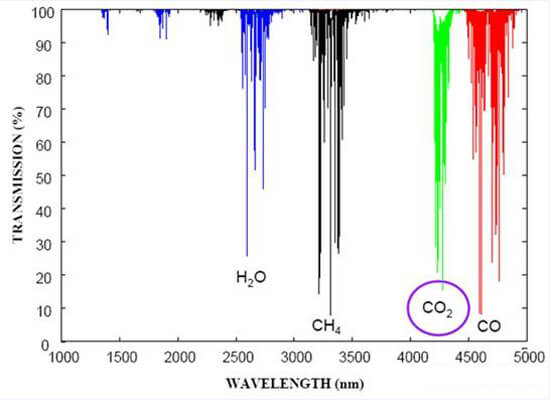

NDIR (non-dispersive infrared) gas sensors emit infrared light to make the gas molecules vibrate. The working principle is that different gases can absorb different infrared wavelengths. The more gas there is, the less infrared light can pass through. When infrared rays pass through the gas in the measurement area, the infrared rays resonate with the gas molecules and are absorbed by the gas molecules when the molecules vibrate.

This weakens the transmitted infrared rays. Gas molecules vibrate at different frequencies. Some atoms are very small and light, so they vibrate at high frequencies. For example, the methane molecule’s vibration frequency is 333KHz, and the central wavelength is 3.3um. Because the molecular weight is different, the infrared absorption wavelength is also different, as shown in the following figure:

- Advantages: 1. Common sensors on the market, such as catalytic combustion (CAT), electrochemical (EC), and semiconductor sensors, cannot measure any gas. For example, CO2 cannot be measured, but NDIR sensors can measure CO2. The most commonly measured gases for NDIR are CH4 and CO2.

- 2. Oxygen is not required. The CAT sensor requires oxygen to participate in the oxidation reaction. But NDIR is an optical sensor and doesn’t require oxygen to be involved.

- 3. The measurement concentration can reach 100%v/v. Because the NDIR sensor signal characteristics are: in a normal environment, the signal strength is the largest; the greater the measured gas concentration, the smaller the signal.

- 4. Good stability. NDIR sensor stability basically depends on the light source. As long as a good light source is selected, the long-term stability will be excellent, and it can be achieved without calibration for 2 years.

- 5. Low maintenance cost.

- Disadvantages: NDIR sensors consume high power. Measuring gas concentrations at the ppm level is expensive. The structure, software and hardware are more complex, and the price is relatively expensive.

4. Catalytic Gas Sensors

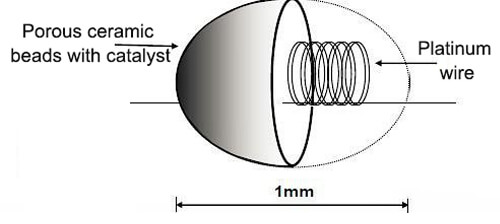

This sensor is actually a gas detector based on a platinum resistance temperature sensor. A high temperature resistant catalyst layer is prepared on the surface of the platinum resistor, and at a certain temperature, the combustible gas is catalytically burned on the surface. Therefore, the platinum resistance temperature increases, resulting in a change in the resistance value.

Since the catalytic gas sensor platinum resistance is usually wrapped by porous ceramic beads, this sensor is also called a catalytic bead gas sensor. In theory, this sensor can detect all combustible gases, but there are many exceptions in practical applications. This sensor can usually be used to detect combustible gases such as methane, LPG, acetone, etc. in the air.

- Advantages: Strong resistance to harsh climate and poisonous gas, long service life. Can detect all flammable gases, including alkanes and non-alkanes. Low maintenance cost.

- Disadvantages: work in the dark, easy to explode or catch fire. Components are susceptible to poisoning by sulfide and halogen compounds, which shorten their service life. In a hypoxic environment, the error is larger.

This sensor is mainly used to detect combustible gases, such as gas generating stations, and gas plants to analyze CO, H2, C2H2, and other combustible gases in the air.

5. Magnetic Gas Sensors

After the magnetic gas sensor senses heat, light, radiation and pressure in the environment, its magnetic properties will also change accordingly. Using this feature, various reliable and high-sensitivity sensors can be made. Magnetic gas detectors are mostly magnetic probes with relatively strong measurement capabilities. When measuring gases, it is common to use the high magnetic properties of oxygen to measure the oxygen concentration. Because oxygen in the air can be attracted by strong magnetic fields. Commonly used are thermal magnetic convection oxygen analysis sensors and magneto-mechanical oxygen analysis sensors.

- Advantages: Detects oxygen with excellent selectivity. Magnetic oxygen analyzers are highly accurate.

- Disadvantages: single measurement type, the small application range.

It is commonly used in chemical fertilizer production, cryogenic air separation, thermal power station combustion system, natural gas to acetylene, and other industrial production oxygen measurement. Monitor exhaust gas, tail gas, flue gas and other emissions.

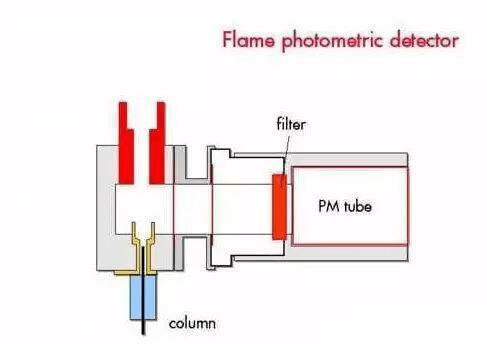

6. Photoionization Gas Sensors

A Photoionization gas sensor (PID) works by using photoion-ionized gas to detect gas. Simply put, the gas is irradiated with ultraviolet light generated by an ion lamp, and the gas will be ionized after absorbing enough ultraviolet light energy. The measured gas level is calculated by detecting the tiny current generated by the gas ionization. It can detect volatile organic compounds and other toxic gases from 10ppb to 10000ppm. Many hazardous substances contain volatile organic compounds, and PID is highly sensitive to volatile organic compounds.

Advantages: PID has high sensitivity, no poisoning problem, safe and reliable. Can detect more than 400 types volatile organic gases.

Disadvantages: cannot measure air, toxic gases and natural gas, etc.

It is the most sensitive device for detecting organic volatiles, especially for those gas leaks with very low concentrations, which has incomparable advantages compared to other detectors.

7. Thermal Conductivity Gas Sensors

A thermal conductivity gas sensor is a device that can sense a certain gas in the environment. It converts gas concentration information into electrical signals for detection, monitoring, analysis and alarming. Thermally conductive gas-sensitive materials measure their concentration based on the difference in thermal conductivity between different gases and air. Usually, a change in thermal conductivity is translated into a change in resistance through the circuit. The gas type and level are calculated from the change in resistance value.

Advantages: wide detection range, the highest detection concentration can reach 100%. Good working stability, long service life, no catalyst aging problem.

Disadvantages: poor detection accuracy, low sensitivity, temperature drift.

This gas sensors are widely used in chemical, coal, military, environmental, etc., only to better optimize the sensor performance.

8. Gas Chromatograph Analyzer

Based on chromatographic separation technology and detection technology, various gas samples are separated and measured. Hence the full analytical sensor. It has been used in power plant boiler tests.

During work, a certain gas sample is periodically taken from the sampling device. The chromatographic column is carried by a pure carrier gas (ie mobile phase) with a certain flow rate, and the chromatographic column is filled with a solid or liquid called a stationary phase. The components are repeatedly distributed in the two phases, and flow out of the chromatographic column according to time and enter the detector for quantitative determination.

- Advantages: high sensitivity, suitable for micro and trace analysis, and can analyze complex multiphase separation gases.

- Disadvantages: Regular sampling cannot achieve continuous sampling and analysis, and the system is more complicated. It is mostly used for laboratory analysis, and is not suitable for industrial field gas monitoring.