Table of Contents Since the dawn of industrial development, the emission of various toxic gases and solid waste has continuously

Industrial Pressure Sensor Suppliers

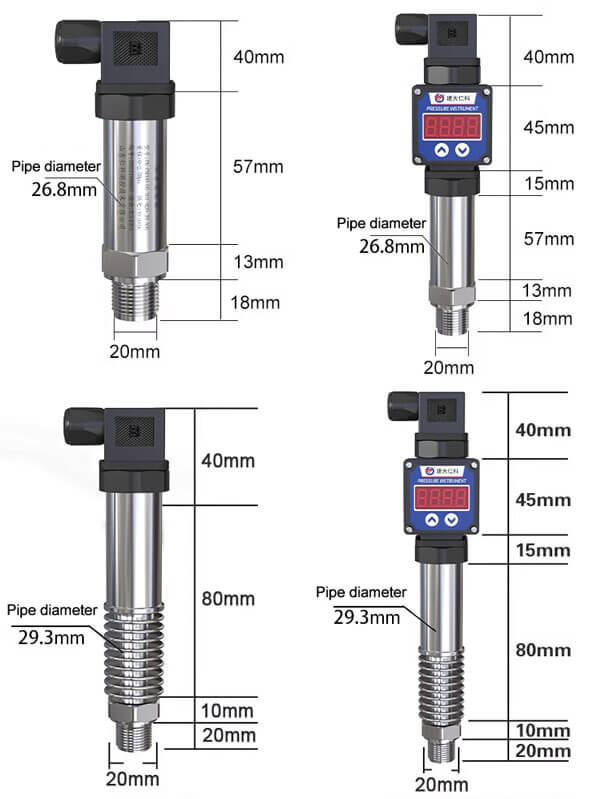

The pressure sensor is small in size, easy to install, and is insulated by a stainless steel case. It is suitable for measuring gas and liquid media compatible with the material of the contact part. It can be used to measure gauge pressure, negative pressure, and absolute pressure.

- Model: RK-PM301-*-N01-*

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: $33~$67

Renke Pressure Sensor

Our pressure sensors use the standard ModBus-RTU communication protocol with RS485 output, which allows integration with PLCs, configuration software, configuration screens, and industrial controllers. We recommend selecting our company’s matching monitoring host, which can upload data to our free cloud monitoring platform. This platform supports users in viewing real-time data, historical data, alarm records, and more via mobile phones or computers. If you choose a model with buttons and a display, you can modify values such as the address and baud rate directly through the buttons.

Pressure sensor features

Our RS-CYL-*-1-*-EX is equipped with a stainless steel diaphragm silicon piezoresistive pressure sensor. It uses laser trimming technology for zero-point and temperature performance compensation and undergoes rigorous testing of components, semi-finished products, and final products. The pressure sensor is calibrated at multiple points using imported high-precision pneumatic or hydraulic sources, ensuring high accuracy and stable performance. Its casing is made from stainless steel with corrosion-resistant material, making it suitable for measuring gases or liquids that are compatible with the materials in contact with the sensor. It can measure gauge pressure, negative pressure, and absolute pressure. An optional Hirschmann interface output is available for convenient field wiring.

Pressure sensor applications

The pressure sensor is suitable for the measurement of industrial process control pressure. Widely used in water plants, oil refineries, sewage treatment plants, building materials, light industry, machinery and other industrial fields to achieve measurement of liquid, gas and steam pressure. For more details, please check the pressure sensor video.

Pressure sensor datasheets

| Power supply | 10~30V DC |

|---|---|

| Max. power consumption | 0.3W |

| Measure range | -0.1~100MPa (optional) |

| Accuracy | 0.5%FS (default), 0.2%FS |

| Overload capacity | ≤1.5 times (continuous) ≤2.5 times (instantaneous) |

| Temperature drift | 0.03%FS/℃ |

| Medium temperature | -40~75℃, -40~150℃ (high temperature type) |

| Working environment | -40~60℃ |

| Monitoring target | non-corrosive gas or liquid |

| Output method | RS485 |

Pressure sensor range

| Code | Range | Code | Range | Code | Range | Code | Range |

|---|---|---|---|---|---|---|---|

| 01 | 0-10kPa | 02 | 0-100kPa | 03 | 0-0.6MPa | 04 | 0-1MPa |

| 05 | 0-2.5MPa | 06 | 0-10MPa | 07 | 0-40MPa | 08 | 0-60MPa |

| 09 | -100-0kPa | 10 | -0.1MPa-1MPa | 11 | 0-1.6MPa | 12 | -0.1MPa-0.1MPa |

| 99 | Customized range | ||||||

| Ranges below 5kPa can only measure dry gas | |||||||

| Ranges ≥ 60MPa, thread can only be M20*1.5 | |||||||

Pressure Sensor Use

1. Our products are equipped with instructions for use and certificates of conformity. There are technical parameters, please check carefully to avoid mistakes.

2. According to the product connection method and thread type, check whether the field interface is consistent with the product interface. When connecting, it should be tightened slowly. The torque cannot be directly applied to the transmitter housing. It can only be added to the hexagonal interface of the pressure interface. on. Ensure that the transmitter is mounted perpendicular to the ground. Use a wrench to tighten the transmitter from the hexagonal nut at the bottom of the transmitter during installation to avoid direct rotation of the transmitter.

3. When connecting the power supply, it should be connected in strict accordance with the wiring instructions of our company.

4. This product is a precision instrument. It is forbidden to disassemble at will, to prevent collision and fall. It is strictly forbidden to touch the sensor diaphragm with a sharp object, thus causing damage to the core.

5. The transmitter can be used after power-on. After preheating for 30 minutes, the output is more stable. If an abnormality is found during use, turn off the power, stop using it, check it, or contact our technical department directly.

6. During the pressure measurement process, slowly pressurize and depressurize, avoid adding to high pressure or reduce to low pressure instantaneously. If measuring the pressure with faster change speed, install pressure buffer at the connection outlet of the transmitter and the measured medium. Device.

7. The human factors caused by pressure overload, wiring error, sensor diaphragm damage, etc. are not covered by the warranty.

Related Blogs

Table of Contents Did you know? Atmospheric pressure is constantly influencing the natural phenomena around us—everything from the direction of

Table of Contents What is differential pressure? Differential pressure is the difference between the values of the pressures at different

Table of Contents What is a vibration sensor? Vibration sensor is a device that measure the vibration speed and frequency

Measuring tilt angles is an important part of geometric metrology. The range of angle measurement is wide. According to the

Table of Contents Smart buildings are the product of the development of modern science. The smart building system is mainly

Table of Contents Have you or your friend experienced a broken water pipe, water accumulation in the kitchen or bathroom?

Table of Contents What is a water level sensor? A water level sensor is a device designed to measure the

Table of Contents What are industrial sensors and actuators? Industrial sensors are devices that can convert physical or chemical quantities