Table of Contents What is differential pressure? Differential pressure is the difference between the values of the pressures at different locations. For example, if the

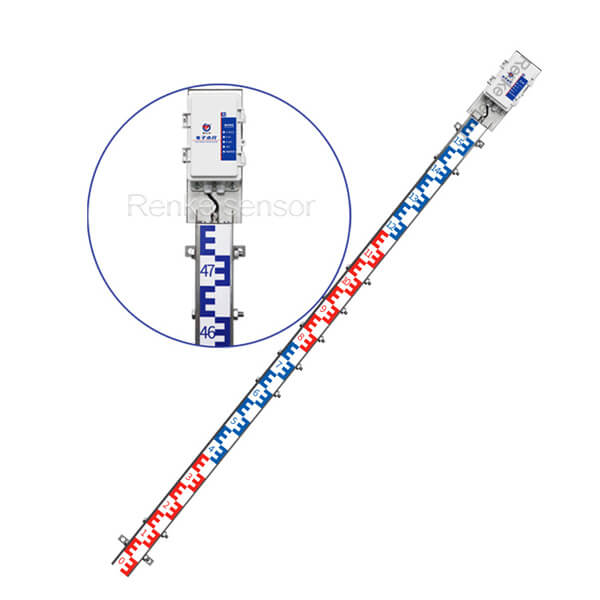

Differential Pressure Sensor

RS-YC-N01-2D-EX and RS-YC-N01-AL-EX differential pressure sensors are wall mouted types and have rs485 output. They have a range of -10kPa~10kPa and with LCD display. The differential pressure sensor is designed with reverse polarity protection and instantaneous overcurrent and overvoltage protection, meeting EMI protection requirements. Widely used in pressure measurement in clean rooms, boilers, vacuum cleaners, air conditioners, etc.

- Model: RS-YC-N01-2D-*-EX/RS-YC-N01-AL-*-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price:$46.2

Differential Pressure Sensor View

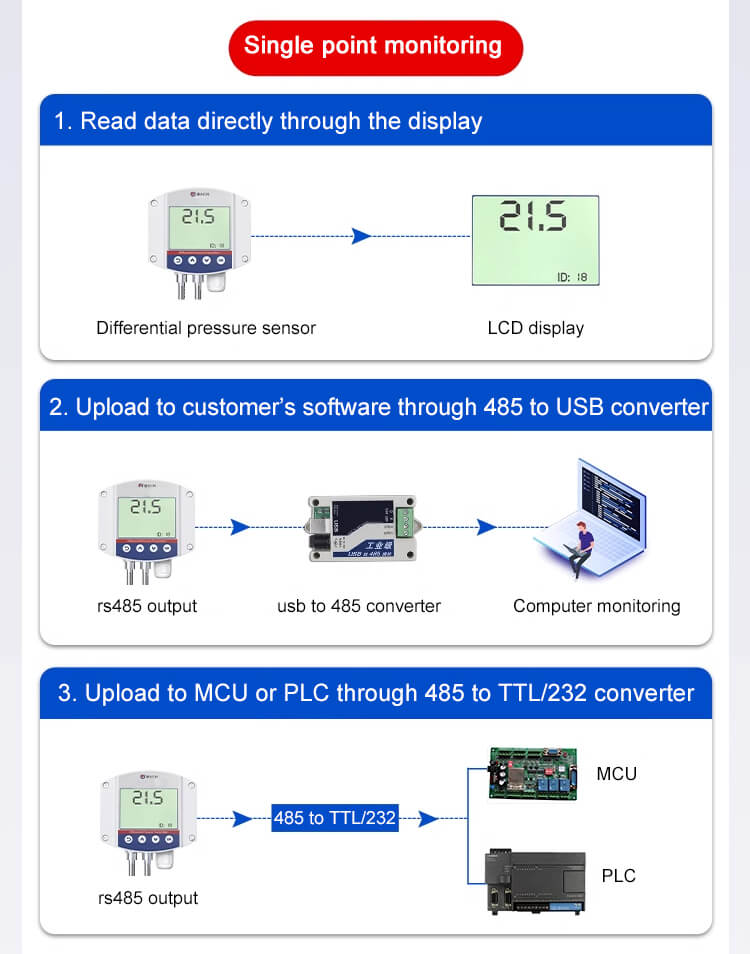

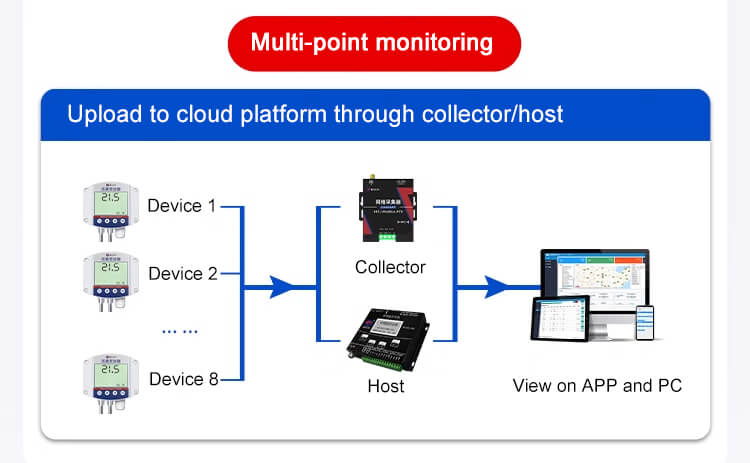

The RS-YC-N01-2D-EX and RS-YC-N01-AL-EX differential pressure sensors have a built-in MEMS pressure sensor and a dedicated conditioning chip. It utilizes advanced pressure sensor technology and low-power, high-precision digital processing technology to provide complete pressure calibration and temperature compensation. Adopting rs485 communication interface standard ModBus-RTU communication protocol, the communication distance is up to 2000 meters, and it can be connected to on-site PLC, configuration software, configuration screen and industrial controller. With our matching network concentrator, the monitoring host uploads data to our free monitoring cloud platform, and you can view real-time data, historical data, alarm records, etc. via browser or cell phone APP.

| Power supply | DC10~30V |

| Power consumption | 0.3W (less than 0.1W without display) |

| Signal output | RS485 |

| Measuring range | -10kPa~10kPa |

| Operating environment | -40℃~+60℃, 0%RH~95%RH (non-condensation) |

| LCD working temperature | -20℃~+60℃ |

| Accuracy | ±1%FS |

| Long-term stability | +0.2%FS |

| Compensation temperature | -5℃~65℃ |

| Pressure interface | Pagoda mouth φ6mm |

| Shell material | Aluminum alloy/ABS plastic |

| Measuring medium | Gas compatible with the contact material Differential Pressure Sensor |

Differential Pressure Sensors

RS-YC-N01-2D-LCD-EX

RS-YC-N01-2D-LCD-EX differential pressure sensor has overpressure protection design, which can withstand 2.5 times of instantaneous pressure. The sensor has internal temperature compensation function to ensure the accuracy of measurement results. Wall mounted installation, optional range of -10kPa~10kPa interval, with LCD display and keypad, manual setting of measuring range. This differential pressure sensor has an ABS plastic housing for measuring gases compatible with the contact material.

RS-YC-N01-AL-LCD-EX

RS-YC-N01-AL-LCD-EX differential pressure sensor is aluminum alloy housing, two pressure interfaces for M10 thread and plug and Ф6 tower head structure. Optional ranges are 0-500Pa, 0-1kPa, 200Pa-200Pa, 500Pa-500Pa, 1kPa-1kPa, -200Pa-0, -500Pa-0, -1kPa-0. Milli voltage, standard voltage, current, frequency signal output are available to choose. It has overload protection function, anti-electromagnetic interference function and temperature compensation function. Zeroing button is available to select the pressure range. LCD screen display is available to choose. Widely used for air or neutral gas detection and control.

How Differential Pressure Sensor Works

When a liquid or gas passes through the high and low pressure chambers, the force they exert on the two ends of the sensor creates a pressure difference. By measuring this pressure difference, we can learn about the flow of the fluid. Specifically, differential pressure sensors typically consist of two measuring membranes. As the fluid passes through the sensor, the force they exert on the two membranes causes the membranes to deform. The sensor will have some resistance or capacitance sensors installed inside the sensor to measure the deformation of the membranes. By calculating the change in resistance or capacitance, we can obtain the pressure exerted by the fluid on the sensor.

If you tell us the specific details such as the installation location, dimensions, etc., we will be happy to provide you with a detailed solution.

Renke technical team

FAQs

Differential pressure refers to the difference in pressure between two points in the system. The expression is ΔP=P1-P2.

Differential pressure sensor is a device used to measure the pressure difference between two objects. Differential pressure sensor is a widely used sensor in industry and science.

Differential pressure sensors are widely used in textile workshop, boiler air supply, underground ventilation and other power, coal, spinning cotton box, dust removal equipment, industry pressure process control field.

Many factors need to be considered when installing a differential pressure sensor, such as protection class, supported fluid type and flow rate range, lateral temperature gradients and zero drift due to temperature changes. For optimum measurement results, install the transducer carefully following the guidelines provided by the manufacturer.

The causes may be:

1. unstable supply voltage.

2. Improper choice of installation location and external interference.

3. There is air leakage or obstruction in the pressure line.

Solution:

1. Check whether the supply voltage is stable, if necessary, use a stabilized power supply.

2. Re-select the installation location to avoid external interference, such as vibration or electromagnetic interference.

3. Check whether there is air leakage or obstruction in the pressure pipe, repair or clean it in time.

The cause may be:

1. Improper selection of the installation location, resulting in the pressure sensor is subject to lateral force.

2. Temperature gradient or unevenness exists in the pressure line, causing sensor temperature error.

3. aging or damage to the sensor.

Solution:

1. Re-select the installation position to avoid the influence of lateral force on the pressure sensor.

2. Ensure that the temperature of the pressure pipeline is uniform, and take insulation measures to reduce the temperature error.

3. Regularly check and replace the aging or damaged sensors.

The cause may be:

1. The temperature sensor is faulty or not calibrated in time.

2. Ambient temperature fluctuates greatly, exceeding the temperature compensation range.

Solution:

1. Check whether the temperature sensor is working properly and calibrate it as required.

2. If the ambient temperature fluctuation is large and beyond the temperature compensation range, consider taking temperature isolation measures or using a pressure transmitter with a larger temperature range.

Related blogs

Table of Contents The dew point depends on how much water vapor is present in the air. If the air is very dry with few

Table of Contents What is a vibration sensor? Vibration sensor is a device that measure the vibration speed and frequency of mechanical motion and convert

Table of Contents With the development of technology, the Internet of Things (IoT) has become an indispensable part. It connects a variety of devices and

Long-term rainfall and melting snow have raised water levels and flooded city roads, causing flooding. Frequent and extreme flooding is inevitable and endangers community safety.

Table of Contents Water is the source of life, integral to every aspect of human production and daily living. In many scenarios, ensuring health and

Table of Contents Have you or your friend experienced a broken water pipe, water accumulation in the kitchen or bathroom? Water is the most common