Table of Contents Gas leaks pose serious dangers in residential environments, including potential fire hazards, explosions, and adverse health effects.

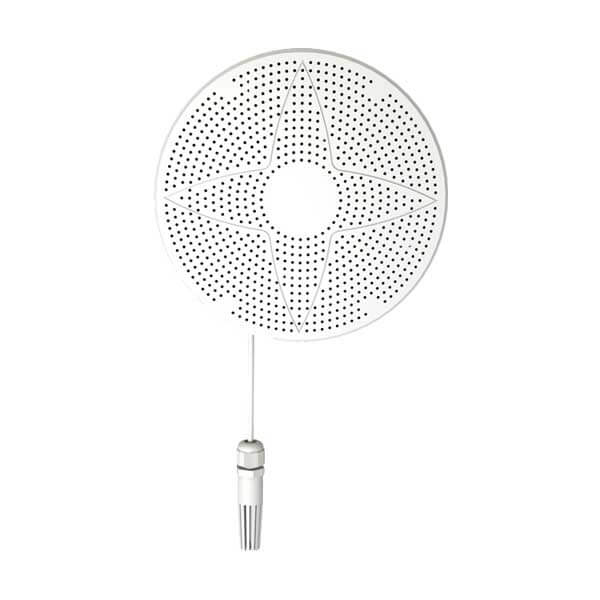

Carbon Monoxide Sensor

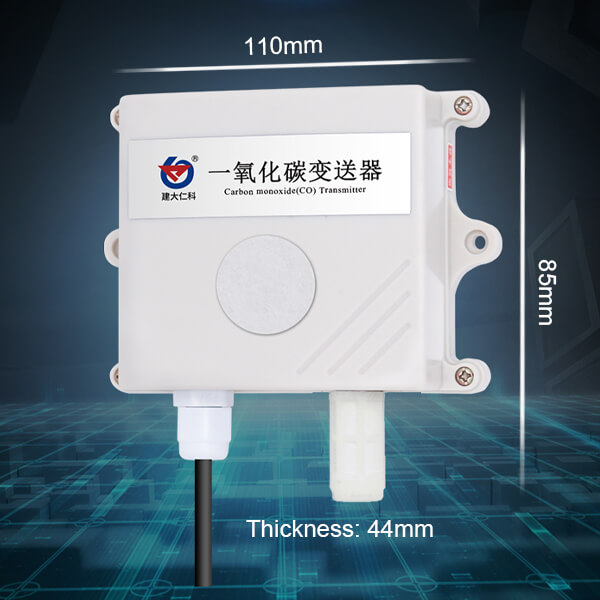

RS-CO-*-2-EX carbon monoxide sensor is an industrial gas sensor, which is mostly used in industries, buildings, mines, and other places. The co sensor measuring range is 0-1000ppm and 0-2000ppm for optional, other ranges can be customized. The output mode of this co sensor is 0-5v, 0-10v, 4-20ma, rs485. The carbon monoxide sensor price:

- Model: RS-CO-*-2-EX

- MOQ: 1 PCS

- Delivery date: within 24 hours

- Price: $37.3~$45.7

About - Carbon Monoxide Sensor

This industrial carbon monoxide sensor adopts an imported big brand electrochemical carbon monoxide sensor with high measurement accuracy. Carbon monoxide gas is relatively light and generally concentrated on the top. This co2 sensor is wall-mounted, and the installation height can be adjusted. The shell is made of high-strength waterproof and dustproof material, which can work normally in harsh environments. With our free cloud platform, unified monitoring of multiple locations can be realized.

This wall-mounted carbon monoxide sensor has two-measure ranges of 0~1000ppm and 0~2000ppm. It can measure temperature and humidity at the same time and can add an LCD display for real-time display of data. Support customization and secondary development.

CO sensor datasheets

| Power supply | 10~30V DC |

|---|---|

| Average power consumption | 0.18W |

| CO measure range | 0-1000ppm (default), 0-2000ppm |

| CO accuracy | ±5ppm or ±10% |

| CO resolution | 1ppm |

| Zero drift | ±3ppm |

| Working environment | -20~50℃, 15~90%RH non-condensing |

| Stability | ≤2% signal value/month |

| Response time | ≤30s |

| Warm-up time | ≥5min |

| Repeatability | ≤2% |

| Pressure range | 90~110kPa |

| Output signal | RS485/4-20mA/0-5V/0-10V |

Advantages - CO Sensor

The IoT carbon monoxide sensor is suitable for underground parking lots, garages, workshops, closed living spaces, and other occasions where the concentration of carbon monoxide needs to be detected.

Best co sensor faratures

1. Our carbon monoxide sensor utilizes imported electrochemical sensors from leading international brands, ensuring stability and durability.

2. The carbon monoxide sensor is available with a default measurement range of 0–1000 ppm, with an optional 0–2000 ppm range. Custom ranges can also be provided upon request.

3. It offers high measurement accuracy, with an error margin within ±10% and repeatability within 2%.

4. An optional high-quality OLED display is available, allowing real-time on-site data visualization with clear readability even at night.

5. The device supports a wide DC power supply range of 10–30V, making it compatible with various on-site power sources.

6. The carbon monoxide sensor features a wall-mounted waterproof enclosure that is easy to install and designed with a high protection level, making it suitable for harsh environmental conditions.

Other - Gas Sensors

FAQ - CO Sensor

Carbon monoxide (CO) is a colorless, odorless, and non-irritating toxic gas primarily produced by the incomplete combustion of fuels. Since it cannot be detected by human senses such as sight, smell, or taste, it poses a significant risk when inhaled. CO rapidly binds with hemoglobin in the blood to form carboxyhemoglobin, which inhibits the blood’s ability to carry oxygen. This can lead to tissue hypoxia. Exposure to low concentrations may cause symptoms such as headaches and nausea, while higher concentrations can result in unconsciousness or even death. The risk is especially high in enclosed or poorly ventilated environments.

In daily life, devices such as gas or liquefied petroleum gas (LPG) water heaters, coal stoves, and charcoal heating equipment can easily emit carbon monoxide (CO). In kitchens, gas stoves may also release small amounts of CO when combustion is incomplete. In the transportation sector, vehicle exhaust is a major source of CO in urban areas. In industrial, facilities such as boiler rooms, smelting furnaces, incinerators, gas plants, and chemical processing areas often rely heavily on carbon-based fuels. Incomplete combustion in these settings can result in significant CO production.

Because carbon monoxide (CO) is imperceptible to human senses, CO poisoning incidents often occur suddenly and with severe consequences. Installing a carbon monoxide sensor is one of the most effective measures for preventing such accidents. These sensors continuously monitor the ambient CO concentration and trigger an alarm when levels exceed safety thresholds, prompting personnel to evacuate and implement emergency measures in a timely manner.

Mainstream carbon monoxide (CO) sensors primarily operate based on electrochemical principles. When CO gas passes through a diffusion membrane into the sensing chamber, it reacts with the electrodes to generate an electric current. The magnitude of this current is directly proportional to the concentration of CO in the environment. This sensing method offers high accuracy, strong stability, and excellent anti-interference performance, making it particularly suitable for high-reliability monitoring scenarios such as underground parking garages and industrial sites.

RS485 Output:

Brown wire: Connect to the positive power supply.

Black wire: Connect to the negative power supply.

Yellow wire: Connect to 485-A.

Blue wire: Connect to 485-B.

Analog Output:

Brown wire: Connect to the positive power supply.

Black wire: Connect to the negative power supply.

Blue wire: Connect to the positive CO signal.

Green wire: Connect to the negative CO signal.

When an alarm is triggered, the following actions should be taken immediately:

Quickly open doors and windows to ventilate the area.

Evacuate all personnel to a safe outdoor location.

Turn off all suspicious combustion devices or gas sources.

Call emergency services and seek professional assistance.

Wait for the CO concentration to decrease before re-entering the area.

Never underestimate the alarm or attempt to handle the leak source by yourself.

According to the World Health Organization (WHO) and national standards:

The 8-hour average exposure concentration should not exceed 9 ppm.

The 1-hour exposure concentration should not exceed 35 ppm.

When CO concentration reaches 50 ppm or higher, long-term exposure can pose a serious health risk. Industrial or specialized industry standards may be more stringent and should be set according to the specific application scenario.

The installation location of the sensor significantly impacts its detection effectiveness. It is generally recommended to install the sensor 1.5 to 2 meters above the ground, close to combustion equipment or potential leakage sources. Avoid installing the sensor near ventilation openings, air conditioning vents, or in areas with high humidity or heavy oil fumes.

For residential environments, it is recommended to install the sensor between the bedroom and kitchen. In industrial environments, a distributed installation strategy should be employed to ensure comprehensive coverage for monitoring.

Yes, it can. Renke’s carbon monoxide sensors can be integrated with our self-developed cloud platform, enabling remote access to real-time data, historical analysis, and SMS alerts for exceeding threshold limits. This provides users with digital and intelligent monitoring capabilities.

Yes, they can. Renke offers comprehensive gas monitoring solutions that connect multiple sensors through gateway devices and platform systems, enabling centralized management, regional alerts, and interlocking control (such as activating exhaust systems or shutting off gas valves).

Related Blogs

Table of Contents Carbon monoxide is a colorless and odorless toxic gas at room temperature. People cannot perceive its presence

Table of Contents Modern companies are placing an increasing emphasis on the value of collected data. As a result, central

Why is a gas detector necessary? In the industrial production process, the leakage of flammable, toxic and harmful gases often

Table of Contents What is IoT? IoT is the “Internet of things“. It is an extended and expanded network based

What is an air quality monitor? An instrument used to detect air quality can be called an air quality monitor.

Monitoring of toxic and harmful gases such as formaldehyde and carbon monoxide in the home environment After the renovation of

Gas sensors application in a wide range. Mainly used to detect the concentration of gas, such as carbon dioxide, oxygen,